Product Description

We are a professional CNC machining manufacturer offering precision machining services for custom industrial equipment parts. Our expertise includes aluminum alloys and engineering plastics, delivering reliable and high-quality solutions for global industrial applications.

Key Features & Attributes

Service: Custom CNC machining for industrial equipment parts

Material Options: Aluminum, Stainless Steel, Brass, Titanium, Engineering Plastics (POM, Nylon, PEEK, ABS)

Machining Type: CNC milling, CNC turning, drilling, EDM

Surface Finish: Anodizing, bead blasting, polishing, powder coating

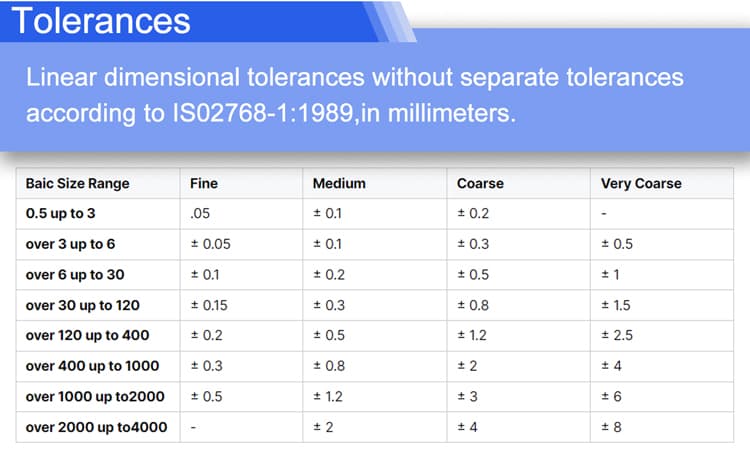

Tolerance: ±0.01mm precision

Custom Design: OEM & ODM service

Applications: Industrial equipment, automation, robotics, aerospace, automotive

Durability: High strength, lightweight, corrosion resistant

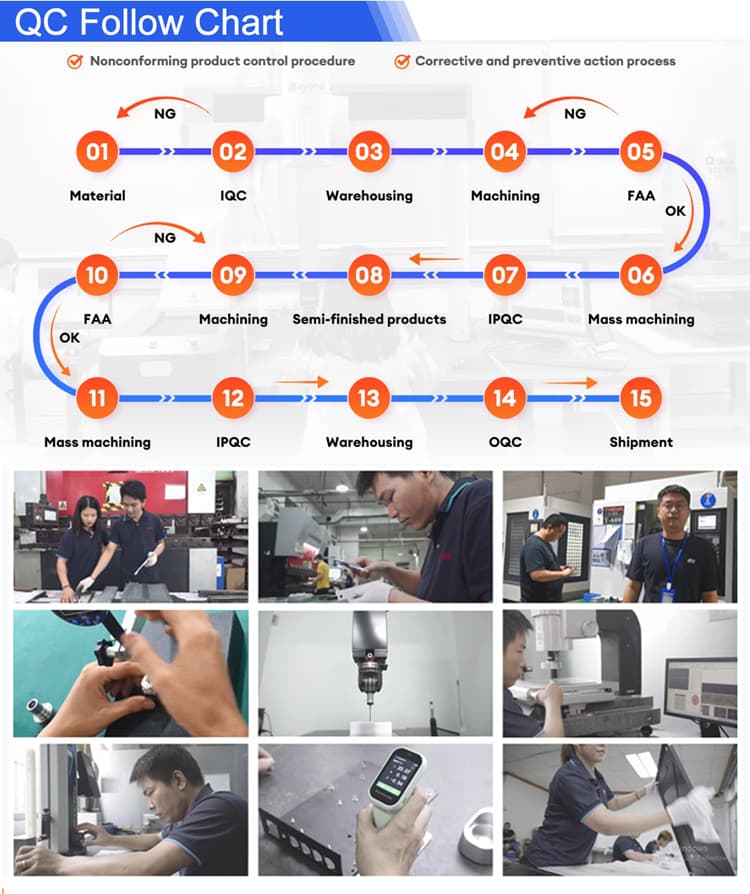

Inspection: CMM, 3D scanning, ultrasonic testing, QC reports

Software: SolidWorks, AutoCAD, CATIA, Mastercam

Prototype Service: Rapid prototyping available

Production Capability: From prototype to mass production

Heat Treatment: Hardening, stress relief, case hardening

Surface Protection: Anti-rust coating, passivation

Assembly Service: Component assembly available

Certification: ISO9001, SGS, RoHS compliant

Lead Time: 5-12 working days, expedited delivery optional

Export Markets: USA, Europe, Japan, Middle East, global supply

Thread Machining: Internal & external threading service

Repeatability: High accuracy for consistent production

Complex Capability: Multi-angle and multi-surface machining

Automation: Robotic machining centers for efficiency

Flexibility: Custom tooling and fixtures

MOQ: Flexible minimum order starting from prototypes

Delivery Options: DHL, FedEx, UPS, air/sea freight

Payment Terms: T/T, PayPal, LC

After-Sales: Technical support and engineering consultation

Innovation: Continuous improvement in machining processes

Protection: Export-grade protective packaging

Testing: Hardness, tensile, and fatigue testing

Customer Service: Dedicated project management support

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-