Product Description

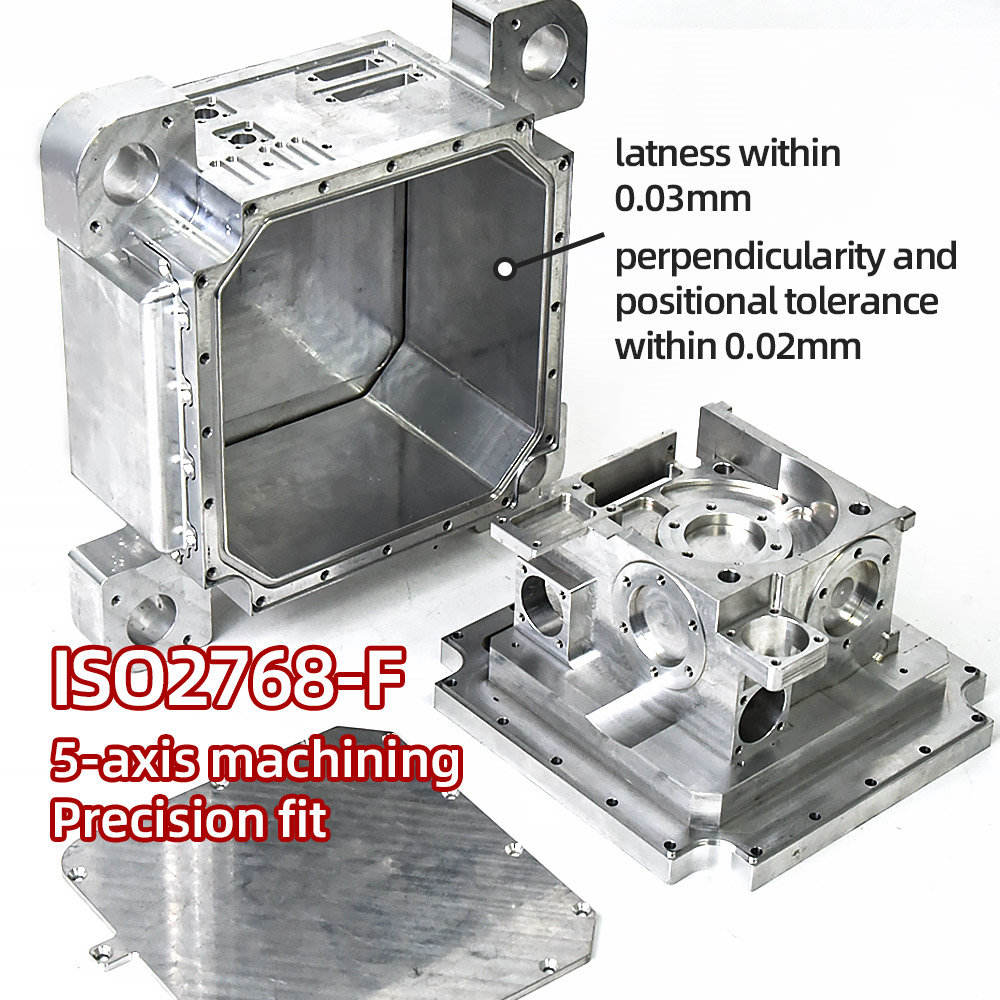

We are a professional ISO2768-FH 5-axis CNC machining manufacturer delivering high-precision custom steel and aluminum parts. Our machining capabilities include complex slot milling at all angles and deep inclined hole drilling, ensuring superior accuracy and durability for demanding applications.

Key Features & Attributes

Standard: ISO2768-FH fine/high tolerance machining

Material: Steel, Aluminum, Stainless Steel, Titanium

Machining Type: 5-axis CNC milling, CNC turning, boring, deep drilling

Specialty: Milling of slots at all angles, deep drilling of inclined holes

Surface Finish: Polishing, anodizing, sandblasting, electroplating

Tolerance: ±0.01mm precision

Design Support: Custom CAD/CAM engineering service

Applications: Aerospace, automotive, robotics, medical devices, heavy machinery

Durability: High load resistance and long service life

Inspection: CMM, ultrasonic testing, 3D scanning, full QC report

Software: SolidWorks, CATIA, AutoCAD, Mastercam

Prototype Support: Rapid prototyping available

Production Volume: Small to large-scale manufacturing

Heat Treatment: Hardening, stress relieving, tempering

Surface Protection: Anti-rust oil, passivation, powder coating

Assembly Service: Sub-component assembly available

Certification: ISO9001, SGS, RoHS

Lead Time: 7-15 days, urgent service available

Export Markets: USA, EU, Japan, Middle East, Global

Thread Processing: Internal & external precision threading

Repeatability: Excellent consistency for mass production

Complex Capability: Multi-angle, multi-surface machining

Automation: Robotic machining center integration

Flexibility: Custom tooling and fixture manufacturing

MOQ: Flexible, from prototype to batch order

Delivery Options: DHL, FedEx, UPS, sea/air freight

Payment: T/T, PayPal, LC

After-Sales: Full technical support and consultation

Innovation: Continuous R&D for machining advancements

Protection: Export-standard protective packaging

Testing: Hardness, fatigue, and tensile strength testing

Customer Service: One-on-one engineering consultation

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-