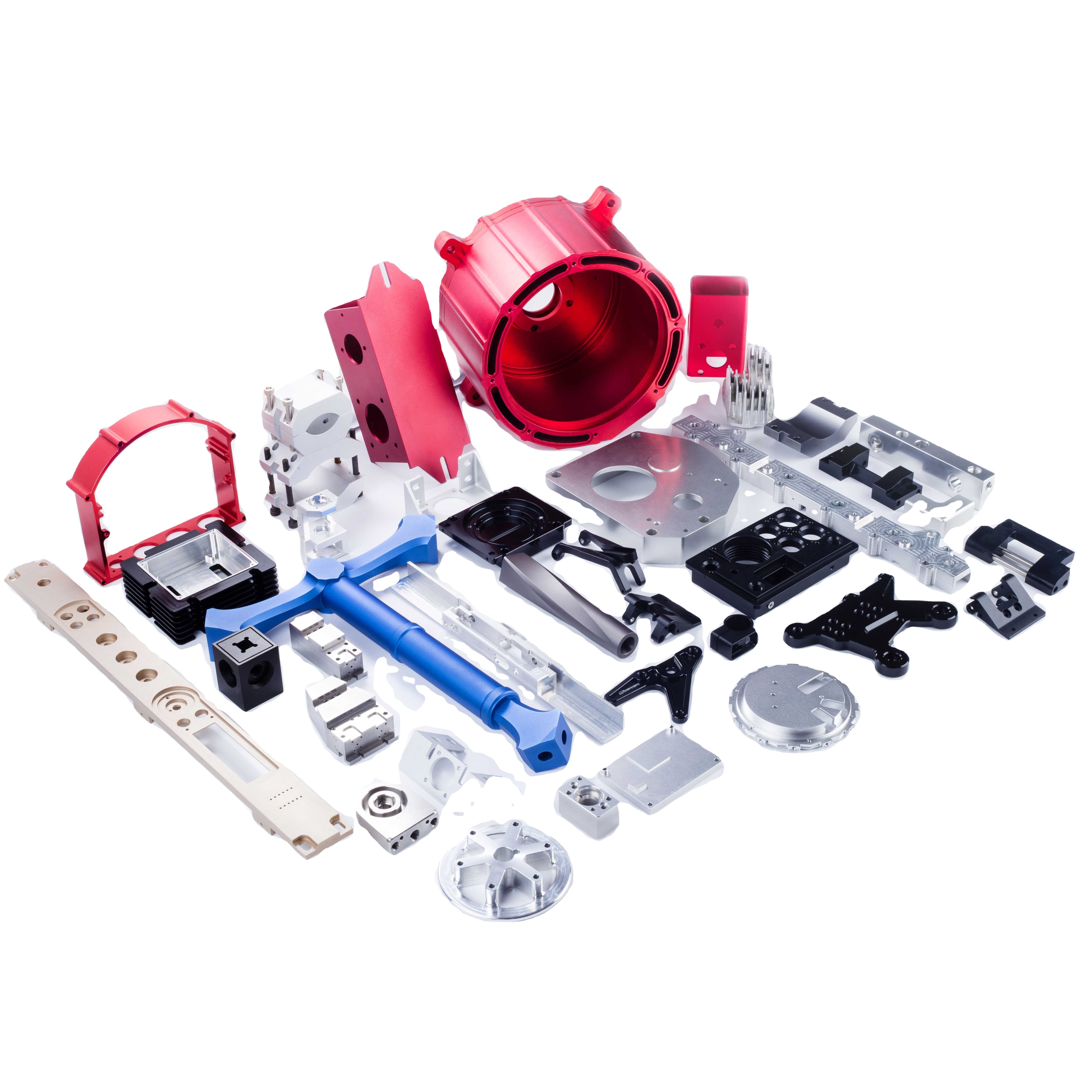

Precision CNC Machined Aluminum Structural Component

Material: Aluminum alloy (e.g. 6061‑T6 or 7075‑T6)

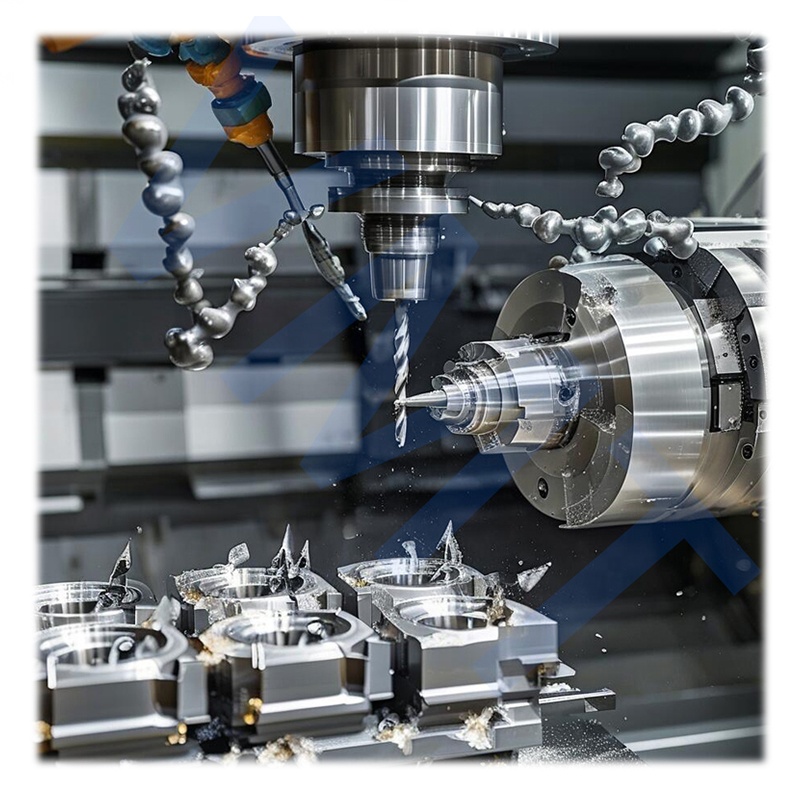

Manufacturing method: CNC milling + CNC turning + 5 axis CNC machining

Axis count: 5 axis CNC milling

Tolerance: ±0.01 mm (or per customer spec)

Surface finish: Machined, Fine finish, Ra0.8 µm (or custom)

Surface treatment options: Anodizing (type II / III), bead blasting, polishing, powder coating, passivation, plating

Corrosion resistance: Yes, with anodized or protective coating

Weight: light (due to aluminum)

Structural integrity: high strength‑to‑weight ratio

Wall thickness: variable, optimized design for rigidity

Cutouts / slots / pockets: multiple geometries visible

Mounting holes: threaded holes, clearance holes

Countersinks / counterbores: present in design

Chamfers / fillets: used to remove sharp edges and improve stress distribution

Geometric features: ribs, flanges, supports

Geometry complexity: moderate to high

Symmetry: partially symmetric structure

Assembly interfaces: mating surfaces, precision fit zones

Fastener compatibility: bolts, screws, studs

Thermal conductivity: good (aluminum property)

Electrical conductivity: moderate (if untreated aluminum)

Lightweight design: yes (structural optimization)

Vibration damping: design consideration included

Finish consistency: maintained across surfaces

Cleanliness: degreased before final packaging

Quality inspection: 100% inspection, CMM, dimensional check

Certification: ISO 9001, RoHS compliance (optional)

CAD formats accepted: STEP / IGES / STL / DWG / DXF

Batch size: prototype to mass production

Lead time: 7–21 days (depending on complexity and quantity)

Packing: foam, anti‑rust oil, sealed in protective packaging

Shipping: air, sea, express (customer‑selected)

Customizable: fully customizable to drawing or sample

Application fields: robotics, automation equipment, aerospace frames, industrial machines

Variants: left / right handed, mirrored, alternate hole patterns

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Custom CNC Milling & 5 Axis CNC Machining Services – Precision Aluminum Parts ISO 2768-M&K

Professional CNC milling and 5 axis CNC machining services for precision aluminum parts, following ISO 2768-M&K standards, with high accuracy, multiple finishes, and full OEM/ODM customization.¥0.00¥0.00 -

ISO 9001 Certified 5-Axis CNC Machining Manufacturer High Precision Custom Parts

We are an ISO 9001 certified manufacturer specializing in high precision 5-axis CNC machining. We provide custom CNC components in aluminum, stainless steel, brass, copper, and engineering plastics. Our products are widely used in automotive, aerospace, electronics, robotics, and industrial applications. OEM/ODM supported, fast delivery, strict quality control.¥0.00¥0.00 -

5-Axis CNC Precision Machined Parts Multi-Material Custom High Accuracy Components

These are high-precision 5-axis CNC machined parts made from aluminum alloy, stainless steel, copper, and other materials. Widely used in machinery, automotive, electronics, and more. Customization is available based on drawings or samples, with excellent surface quality, fast delivery, and quality assurance.¥0.00¥0.00 -

CNC Machining or Not: Cnc Machining

Type: Broaching, DRILLING, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, Steel Machining Services

Micro Machining or Not: Micro Machining

Place of Origin: Guangdong, China

Model Number: cnc machining services

Brand Name: VMT cnc custom part

product name: cnc machining service

Material: Aluminum, Brass, Copper, Titanium, Stainless Steel, Steel Alloys, POM

Processing Type: CNC Turning, CNC Milling, CNC Machining, Grinding, EDM Wire Cutting

Surface treatment: Painting\Powder Coating\Plating\Polishing

Logo Methold: CNC Engraving, Laser Engraving, Screen-Printing

Certification: ISO9001:2008/TS 16949

Application: Machine Industrial equipment Auto Medical Auto parts

company address: Shenzhen Guangdong. China

Serve: Brass Aluminium Stainless cnc machining

delivery time: 7-15 davs

¥0.00¥0.00