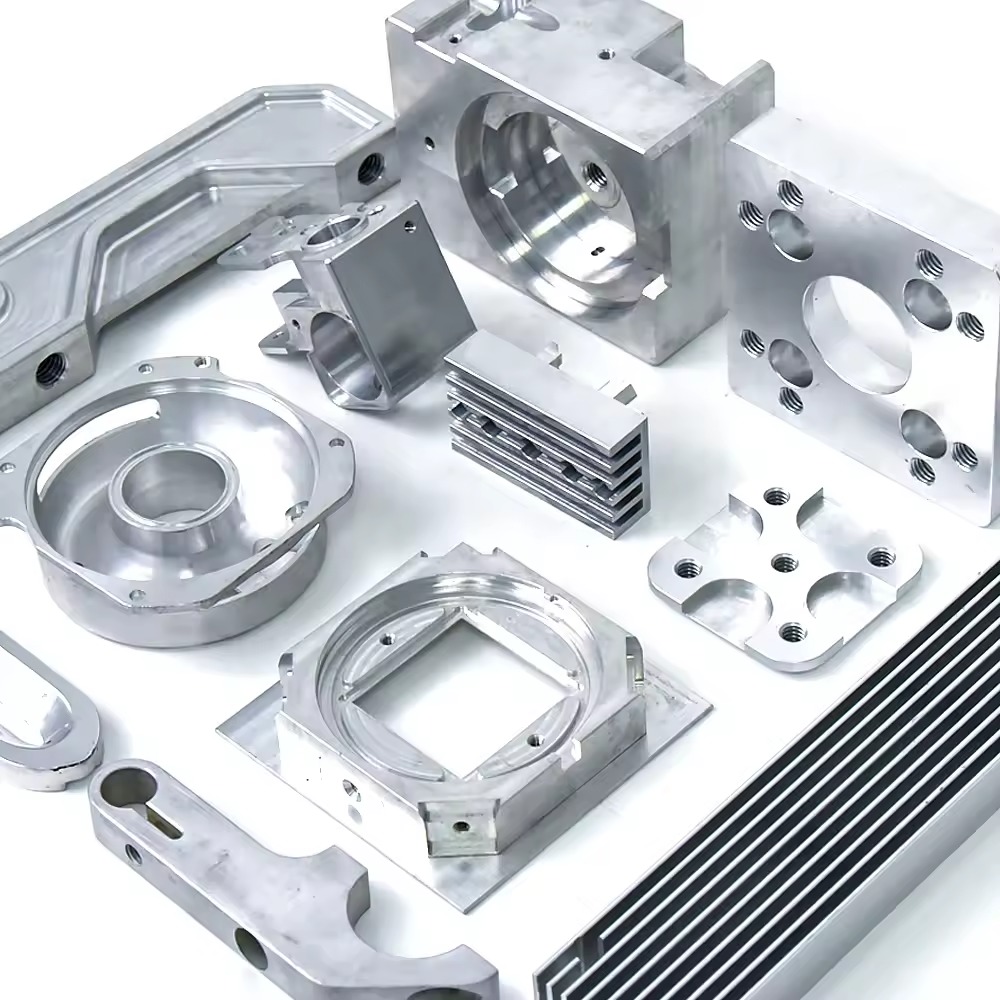

Custom CNC Machined Aluminum Blocks – Housing Modules & Interface Adapters

This batch of precision CNC milled aluminum components is engineered for structural integration in mechanical enclosures, automation systems, and optical modules. Designed with accuracy and function in mind, each part ensures robust mechanical and thermal stability across varied industrial settings.

Key Features:

Square and circular cavities for bearing seats, gearboxes, and sensor bases

Parallel finned aluminum extrusions for passive heat dissipation

Threaded mounting interfaces for modular assembly and servo brackets

Precision bores with counterbores and concentric shoulders

Flat machined reference surfaces for CMM calibration fixtures or laser alignment

Machined with 5-axis and 3-axis CNC milling processes using top-grade 6061/7075 aluminum, maintaining ±0.005mm tolerance and Ra 0.8μm finish.

Surface Treatment: Fine milling, deburring, anodized on request

Functionality: Mechanical housing, sensor carrier, robotic interface

Inspection: 100% dimensional check, hardness & surface test

Export Scope: Germany, Japan, USA, Singapore

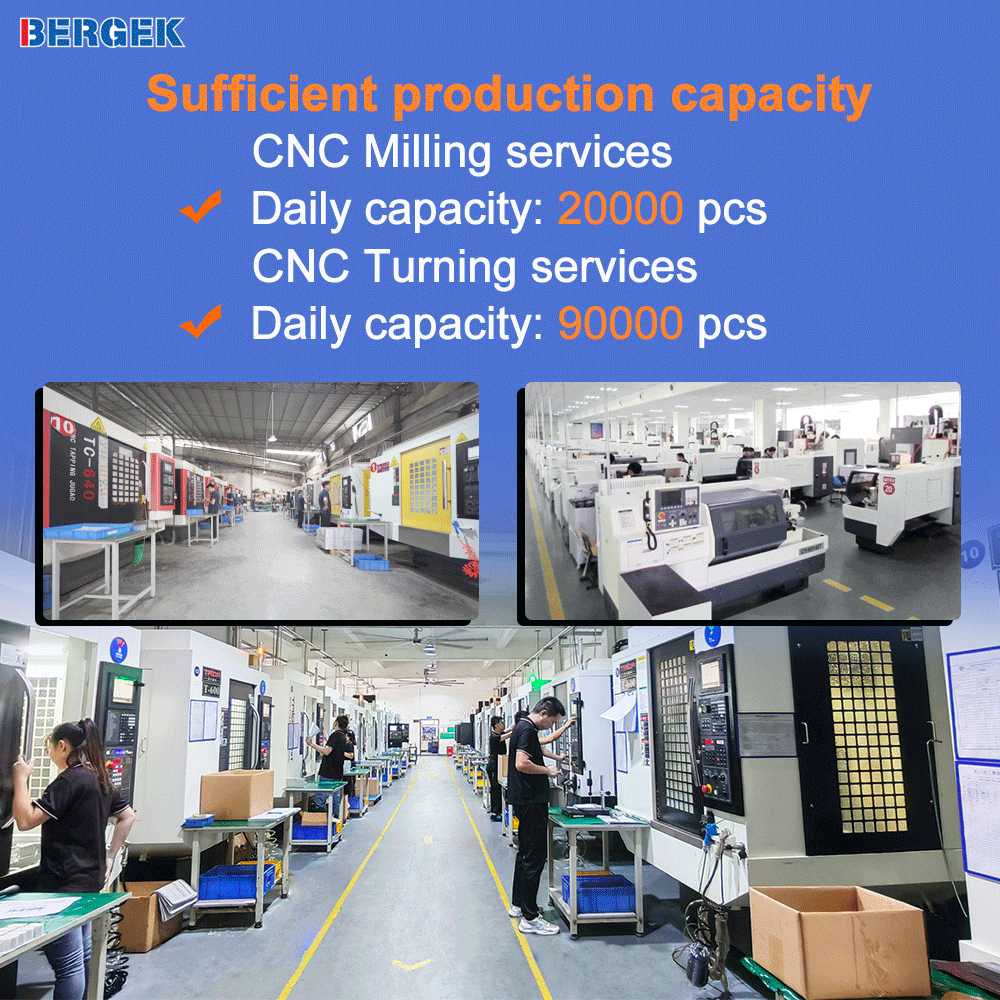

Manufactured by Bergek CNC in Shenzhen, China – Our ISO-certified production line supports rapid prototyping and small-batch customizations.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Custom CNC Milling & 5 Axis CNC Machining Services – Precision Aluminum Parts ISO 2768-M&K

Professional CNC milling and 5 axis CNC machining services for precision aluminum parts, following ISO 2768-M&K standards, with high accuracy, multiple finishes, and full OEM/ODM customization.¥0.00¥0.00 -

Custom 5-Axis CNC Machined Aluminum Parts (6061/7075/2024/5052/6082) - Color Anodized Components

These are custom 5-axis CNC machined aluminum parts made from high-quality alloys such as 6061, 7075, 2024, 5052, and 6082. Featuring color anodized and brushed finishes, our parts are widely used in electronic equipment, automotive, robotics, and more. We support OEM & ODM, fast prototyping, and global shipping with ISO 9001 certified quality.¥0.00¥0.00