5-Axis Machining for Prototyping vs. Mass Production

As a project engineer at BERGEK, an ISO 9001 certified 5-axis CNC machining manufacturer, I am often asked by customers how five-axis technology fits into both rapid prototyping and full-scale manufacturing. With industry trends demanding shorter lead times and higher part complexity, choosing the right CNC process is essential for success from the first sample to stable volume supply.

5-Axis CNC for Prototyping: Fast, Flexible, and Cost-Effective

For prototyping and low-volume runs, CNC prototyping services powered by multi-axis machining offer significant advantages:

- Rapid Turnaround: 5-axis machines allow machining of all faces and features in a single setup, eliminating the need for multiple fixtures or manual repositioning. This cuts programming and cycle times—prototypes can often ship within days.

- Complex Geometry Machining: From organic curves to undercuts and deep cavities, complex parts can be produced in one go, no matter how intricate the 3D model.

- Design Flexibility: Frequent design changes or “engineering for manufacturability” updates are quick to implement, supporting agile product development.

- Cost Efficiency for Small Batches: No need for custom tooling or expensive dies; setup costs are shared over just a few pieces, making it ideal for R&D, new product launches, and market testing.

Typical applications include aerospace CNC prototyping for lightweight structures, automotive CNC prototyping for powertrain and chassis parts, and medical device CNC prototyping for testable implant and surgical components.

5-Axis CNC for Mass Production: Precision and Process Control

When moving from prototype to high-volume production, prototype to production CNC with five-axis machining continues to deliver value:

- Consistent Quality: Advanced CNC process control and automated in-process inspection ensure repeatable, high precision across thousands of parts. Our CNC quality assurance program at BERGEK includes dimensional checks, surface finish verification, and batch traceability.

- Efficient Workflow: Multi-axis machining allows more features per cycle, streamlining even complex assemblies for volume output. Combined with tight tolerance CNC machining and 24/7 production scheduling, this delivers high throughput without sacrificing quality.

- Integrated Supply Chain: As an ISO 9001 CNC machining manufacturer and ISO certified CNC supplier, we provide full PPAP/FAI documentation, material certification, and process validation required by global OEMs.

- Flexible Scale-Up: Whether it’s a transition from pilot batches to serial production or handling high-mix, low-volume orders, our process adapts seamlessly.

Side-by-Side Comparison

| Feature | Prototyping & Low Volume | Mass Production & Supply Chain |

|---|---|---|

| Setup Time | Minimal, fast programming | Optimized for automation, higher setup |

| Tooling/Fixture Cost | Very low | Spread over high volume |

| Change Management | Extremely flexible | Documented, controlled via ISO 9001 |

| Geometry Complexity | No restriction, supports iterative design | Same capability, but with process control |

| Lead Time | Days to 1-2 weeks | As short as hours per batch |

| Typical Use Cases | R&D, market trials, engineering validation | OEM supply, JIT delivery, volume runs |

BERGEK: Your Partner for Every Production Stage

With both CNC prototyping services and mass production capacity under one ISO 9001-certified roof, BERGEK supports your entire product lifecycle. From the first prototype to full-scale supply, our multi-axis CNC machining delivers speed, reliability, and quality assurance.

Contact our engineering team to discuss your next project—no matter the size or complexity, we have the technology and experience to deliver.

READ MORE:

- How 5-Axis Machining Reduces Production Lead Time

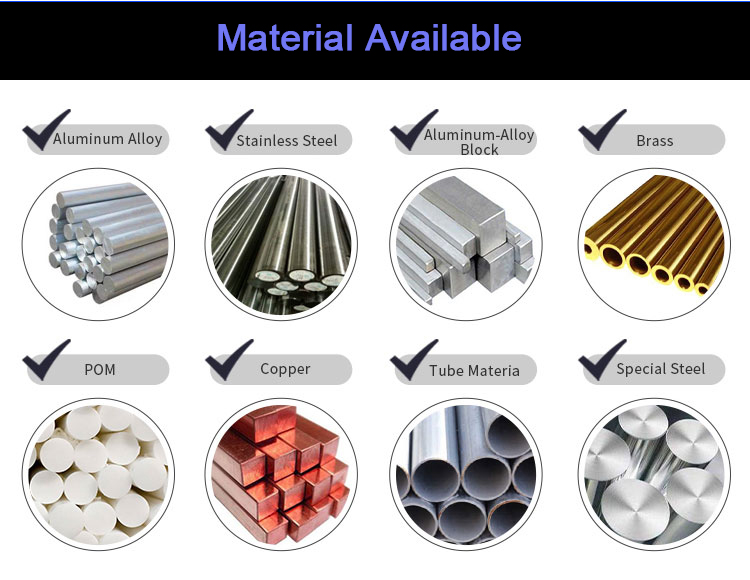

- Materials Suitable for 5-Axis CNC Machining

- Advanced Surface Finishing Techniques in 5-Axis Machining

- Case Study: Complex Mold Manufacturing with 5-Axis CNC

- 5-Axis CNC Machining Cost Factors and Price Calculation

- Quality Control in 5-Axis CNC Machining

- 5-Axis CNC Machining for Customized Parts

- What Industries Need 5-Axis CNC Machining? | Expert Analysis by BERGEK

- 5-axis Machining Tolerances & Surface Finish | Engineering Guide – BERGEK ISO 9001

READ MORE:

- Cost Factors in Precision 5-Axis CNC Machining for Aerospace Components

- How to Choose a CNC Quotation Supplier: Why Partner with Bergek CNC for Your Next Project

- Common Assembly Design Mistakes in CNC Machining and Sheet Metal Fabrication

- Controlling Color Difference in Anodized CNC Machining Parts | Bergek CNC

- How 5-Axis Machining Reduces Production Lead Time

- Materials Suitable for 5-Axis CNC Machining

- Advanced Surface Finishing Techniques in 5-Axis Machining

- Case Study: Complex Mold Manufacturing with 5-Axis CNC

- 5-Axis CNC Machining Cost Factors and Price Calculation

READ MORE:

- Why ISO 9001 Certification Matters When Choosing a CNC Machining Supplier

- Cost Factors in Precision 5-Axis CNC Machining for Aerospace Components

- How to Choose a CNC Quotation Supplier: Why Partner with Bergek CNC for Your Next Project

- Common Assembly Design Mistakes in CNC Machining and Sheet Metal Fabrication

- Controlling Color Difference in Anodized CNC Machining Parts | Bergek CNC

- How 5-Axis Machining Reduces Production Lead Time

- Materials Suitable for 5-Axis CNC Machining

- Advanced Surface Finishing Techniques in 5-Axis Machining

- Case Study: Complex Mold Manufacturing with 5-Axis CNC