From CAD to Prototype: The Rapid CNC Workflow Explained

Introduction

Transforming a digital design into a tangible part depends on a streamlined and precise workflow. Rapid prototyping has become the foundation for modern hardware development, and an experienced cnc machining service bridges the gap from CAD to reality. The demand for precision cnc machining drives every stage, ensuring that even the first prototype is both functional and accurate.

Step 1 — CAD Analysis & Manufacturability Review

The process starts with a thorough evaluation of the CAD model. Early design-for-manufacturability (DFM) checks identify challenging geometries and potential trouble spots. This is where custom cnc machining strategies are mapped out, determining the best approach for turning complex features into physical parts. For specific engineering needs, the workflow may require custom metal parts to match performance or assembly requirements.

Step 2 — Material Selection & Toolpath Programming

Material selection plays a vital role in cost and performance. Aluminum cnc machining is favored for its speed and reliability when producing test components. Careful toolpath programming optimizes efficiency while minimizing material waste and tool wear. When machining aluminum parts, engineers often choose to create an aluminum prototype first, allowing them to evaluate the fit, strength, and thermal behavior under real-world conditions.

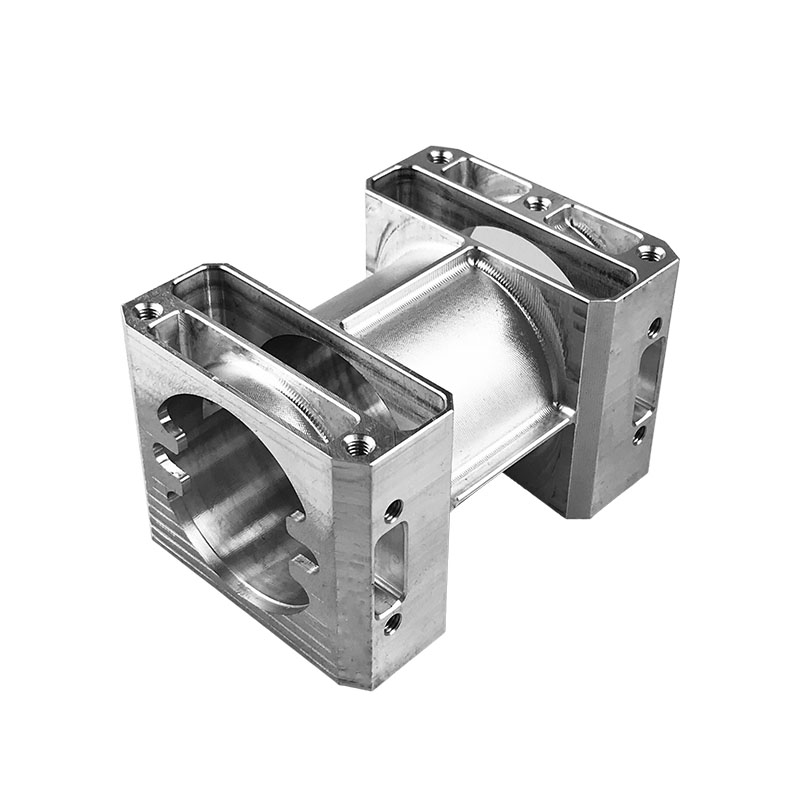

Step 3 — Multi-Axis Machining & Feature Creation

Many advanced designs include deep cavities, angled holes, or intricate contours. Utilizing 5-axis cnc machining enables the creation of these features in a single setup, saving both time and resources. Even for the most detailed parts, precision cnc machining guarantees dimensional consistency. Building a cnc prototype at this stage confirms that the workflow and machine parameters deliver the expected results.

Step 4 — Inspection, Tolerance Checks & Iteration

Quality assurance is at the core of any successful project. Rigorous inspection processes verify tight tolerance and overall part accuracy. The ability to conduct detailed checks supports rapid prototyping by identifying issues early and enabling quick iterations. Reliable results depend on a skilled cnc machining service that maintains process control at every step.

Conclusion

Moving efficiently from CAD to prototype requires a balanced approach to planning, execution, and verification. Rapid prototyping with a capable cnc machining service allows for short development cycles and dependable outputs. The integration of precision cnc machining, iterative aluminum cnc machining, and access to custom metal parts supports innovation without sacrificing speed. Ultimately, this CNC-driven approach to prototype manufacturing sets the standard for accuracy and repeatability in product development.

READ MORE:

- How to Avoid Warping in Thin-Wall Aluminum Prototypes

- Surface Finishing Options for Custom Metal CNC Prototypes

- How Wall Thickness Affects CNC Machined Metal Prototypes

- Understanding Machinability in Custom Metal Parts

- How to Choose the Right Metal for CNC Prototyping

- Aluminum vs Stainless Steel in Prototype Manufacturing

- How Material Properties Affect Rapid CNC Prototype Performance

- Aluminum vs Steel vs Brass: Which Metal Is Best for Rapid CNC Prototyping?

- Why Custom Metal Prototyping Requires Precision CNC Machining