How to Avoid Warping in Thin-Wall Aluminum Prototypes

Introduction

Thin-wall aluminum prototype parts are notorious for warping during the machining process. The combination of low rigidity and high thermal expansion in aluminum makes deformation a real concern, especially in rapid prototyping. Choosing the right cnc machining service is critical for delivering stable, high-precision thin-wall components.

Cause #1 — Machinability-Induced Stress Imbalance

Aluminum cnc machining is popular due to aluminum’s excellent machinability, but thin walls present unique challenges. Machining aluminum parts with reduced cross-sections increases the risk of stress imbalance and deflection. A successful cnc prototype requires special strategies to compensate for these risks during setup and machining.

Cause #2 — Tooling, Toolpaths, and Fixturing

The methods used in precision cnc machining and custom cnc machining play a decisive role in part stability. Selecting the right cutting tools, minimizing tool pressure, and optimizing fixturing are essential to control warping. For high-precision thin-wall parts, the iterative nature of rapid prototyping allows for process adjustments that improve quality with each run.

Cause #3 — Complex Geometry and Multi-Side Machining

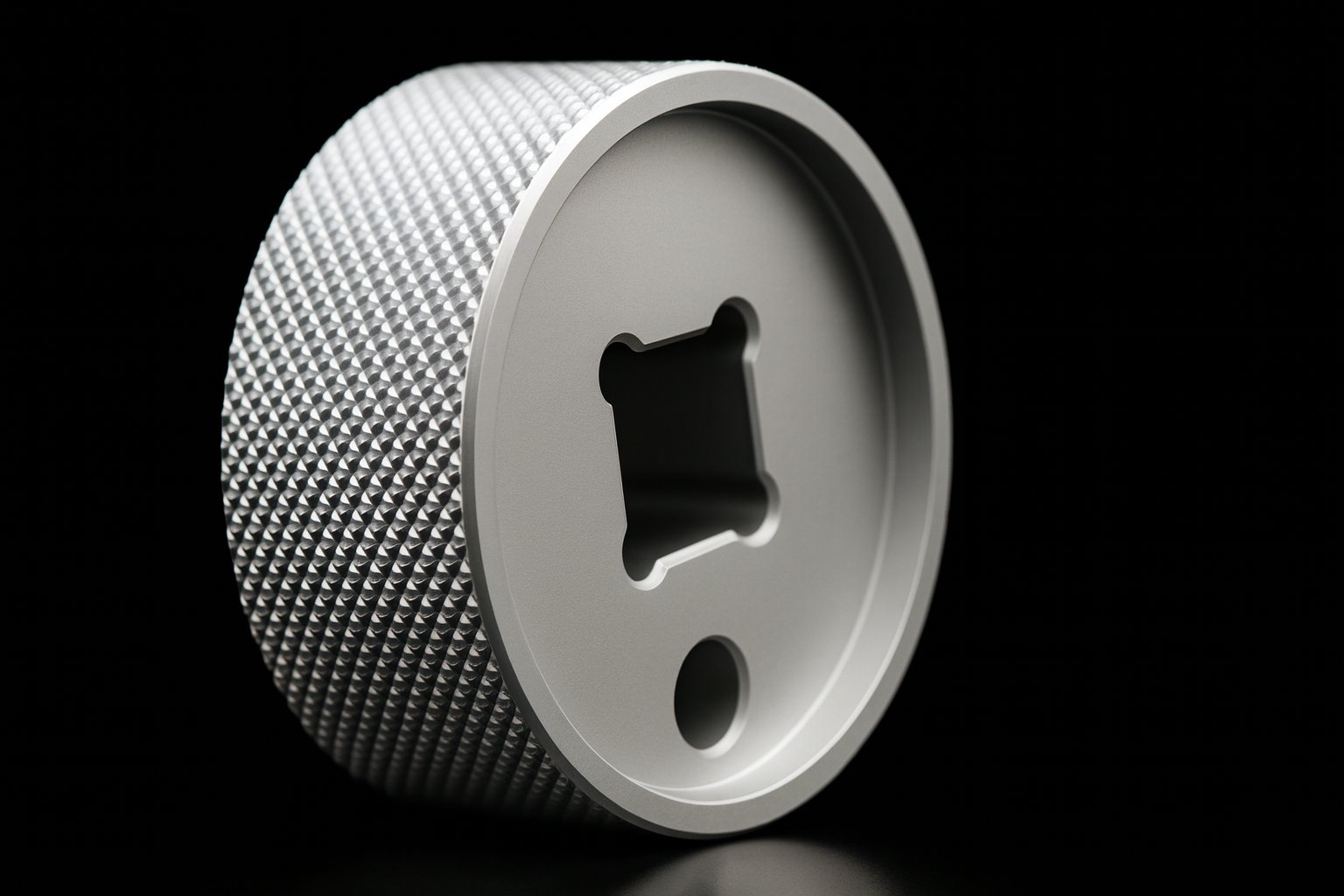

Parts with intricate features or multiple faces are more vulnerable to stress concentrations. This is where 5-axis cnc machining offers clear benefits: it reduces the need for multiple re-fixturing steps, minimizing residual stresses that lead to deformation. Leveraging precision cnc machining and designing with custom metal parts in mind further mitigates the risk of warping.

Solution Layer — Process and Tolerance Strategies

Avoiding warping isn’t just about cutting techniques; it requires a holistic approach to process and tolerance control. Applying tight tolerance specs, stepwise roughing and finishing, and stress-relief machining between stages are all proven methods. Choosing an experienced cnc machining service and relying on consistent custom metal parts supply helps ensure repeatable results for every batch.

Conclusion — Ensuring Stability in Thin-Wall Aluminum Prototypes

The key to stable, high-accuracy thin-wall aluminum prototypes lies in advanced process planning and precise machining. By integrating rapid prototyping, partnering with a skilled cnc machining service, and employing the latest precision cnc machining and aluminum cnc machining techniques, you can optimize prototype manufacturing for even the most challenging designs.

SEO关键词(Tag): rapid prototyping, cnc machining service, precision cnc machining, custom metal parts, aluminum cnc machining, aluminum prototype, cnc prototype, tight tolerance, 5-axis cnc machining, machining aluminum parts, prototype manufacturing, custom cnc machining, thin-wall aluminum, part warping, deformation control, fixturing strategy, machining stress, stress relief, roughing and finishing, process optimization, dimensional accuracy, manufacturing defects, cutting force, feature stability, tool selection, process planning, complex geometry, high-precision machining, production consistency, multi-face machining, rapid iteration, engineering validation, quality control, surface integrity, design for manufacturability, mechanical properties, batch repeatability, advanced CNC, feature integration, thin-wall design.

READ MORE:

- Surface Finishing Options for Custom Metal CNC Prototypes

- How Wall Thickness Affects CNC Machined Metal Prototypes

- Understanding Machinability in Custom Metal Parts

- How to Choose the Right Metal for CNC Prototyping

- Aluminum vs Stainless Steel in Prototype Manufacturing

- How Material Properties Affect Rapid CNC Prototype Performance

- Aluminum vs Steel vs Brass: Which Metal Is Best for Rapid CNC Prototyping?

- Why Custom Metal Prototyping Requires Precision CNC Machining

- From CAD to Prototype: The Rapid CNC Workflow Explained