Best Aluminum Grades for Precision CNC Machining (6061/7075/2024)

Introduction — Why Aluminum Grade Selection Matters in CNC Prototyping

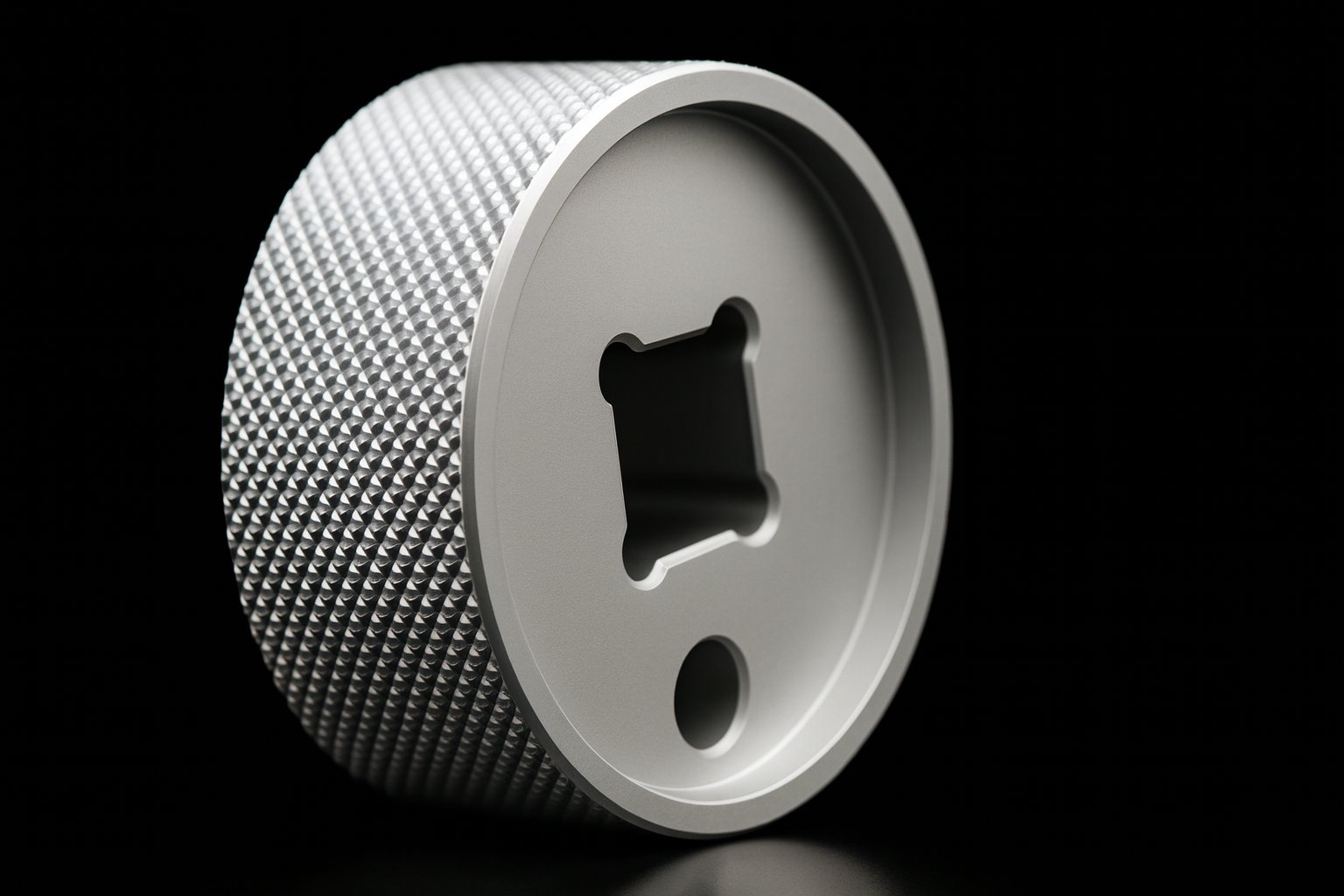

Choosing the right grade of aluminum directly affects the performance of CNC prototypes. Different aluminum grades impact machinability, strength, and precision, making grade selection a key factor for successful aluminum cnc machining, rapid prototyping, and reliable cnc machining service. For engineers, these material choices translate into real-world results in both function and manufacturability.

6061 Aluminum — Excellent Machinability and Versatility

6061 aluminum is the most commonly used grade for machining aluminum parts due to its excellent balance of machinability, strength, and cost. It is ideal for a broad range of applications, especially when developing an aluminum prototype that requires quick iteration and high surface quality. Thanks to its composition, 6061 is well-suited for precision cnc machining and provides a solid foundation for most general prototype projects.

7075 Aluminum — Superior Strength with Machining Challenges

7075 aluminum offers much higher strength compared to 6061 but comes with increased machining difficulty. It is preferred for cnc prototype projects requiring robust structural properties or where weight-to-strength ratio is critical. However, engineers should be aware that custom metal parts made from 7075 may take longer to process and demand more advanced precision cnc machining techniques to achieve accurate results.

2024 Aluminum — High Fatigue Resistance and Specialized Use

2024 aluminum is prized for its outstanding fatigue resistance and high strength, making it suitable for demanding applications such as aerospace and high-load components. Complex parts often require custom cnc machining or even 5-axis cnc machining to fully realize the geometry. For rapid prototyping in situations that simulate real-world stress or vibration, 2024 is an excellent choice.

How Grade Choice Impacts Tolerance, Speed & Stability

Material grade directly influences the achievable tight tolerance, machining speed, and dimensional stability. 6061 usually allows for faster machining and easier tolerance control. In contrast, 7075 and 2024, while stronger, may need more careful handling to ensure tight tolerance is met. The expertise of the cnc machining service and the characteristics of the custom metal parts determine the final result.

Conclusion — How to Choose Between 6061, 7075, and 2024

For most rapid prototyping projects, 6061 is a dependable choice for aluminum cnc machining and general prototype manufacturing. When higher strength or fatigue performance is required, 7075 and 2024 provide robust alternatives, though they may require more advanced precision cnc machining and a tailored cnc machining service. Each material has its place—selecting the right grade is critical to a successful, cost-effective, and functional prototype.

Strongly Associated SEO Keywords (for internal linking):

- rapid prototyping

- aluminum cnc machining

- cnc machining service

- precision cnc machining

- custom metal parts

- aluminum prototype

- cnc prototype

- tight tolerance

- 5-axis cnc machining

- machining aluminum parts

- prototype manufacturing

- custom cnc machining

- cnc rapid prototyping

- low volume cnc machining

- aluminum part design

- prototype validation

- cnc machining quality

- cost-effective prototyping

- cnc prototyping benefits

- high precision cnc machining

- aluminum surface finishing

- advanced prototype manufacturing

- product development

- design for manufacturability

- functional prototype

- cnc manufacturing process

- engineering prototype

- prototype testing

- dimensional accuracy

- iterative prototyping

- quick-turn prototyping

- manufacturing lead time

- surface treatment options

- heat dissipation parts

- complex geometry machining

- structural prototype

- assembly validation

- high tolerance prototype

- rapid prototype machining

- CNC design optimization

READ MORE:

- Avoiding Chatter and Burrs in Aluminum CNC Prototyping

- Common Failures in Aluminum CNC Machining and How to Prevent Them

- Aluminum vs Magnesium: Which Is Better for Prototyping?

- Tolerance Control Techniques for Aluminum CNC Machining

- Aluminum Prototype Housing for Robotics and Automation

- How Surface Treatment Affects Aluminum Prototypes (Anodizing, Bead Blast)

- CNC Toolpath Strategies for High-Precision Aluminum Components

- How to Improve Accuracy When Machining Aluminum Parts

- Why Aluminum Is the Most Popular Material for CNC Rapid Prototyping