Case Study: How a Failed Mold Wasted $4,500 and Two Months of Time-to-Market — And Why the Client Chose BERGEK CNC Instead

In manufacturing, the success of a product often depends on the quality of the mold used to produce it.

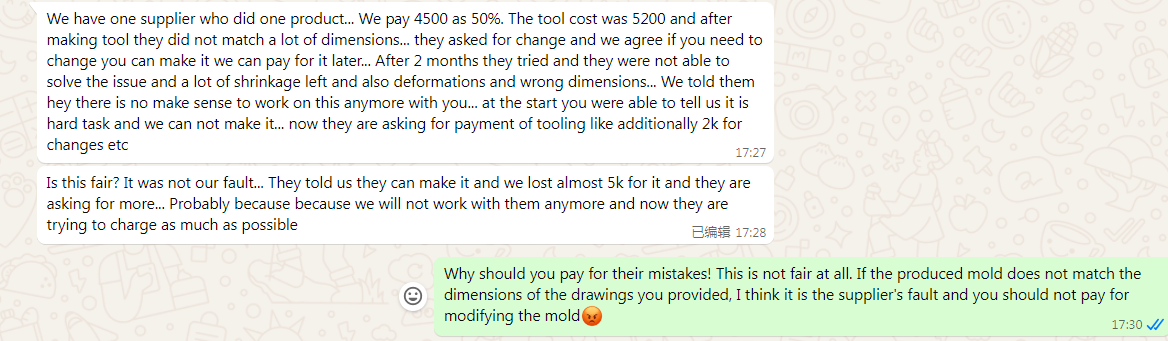

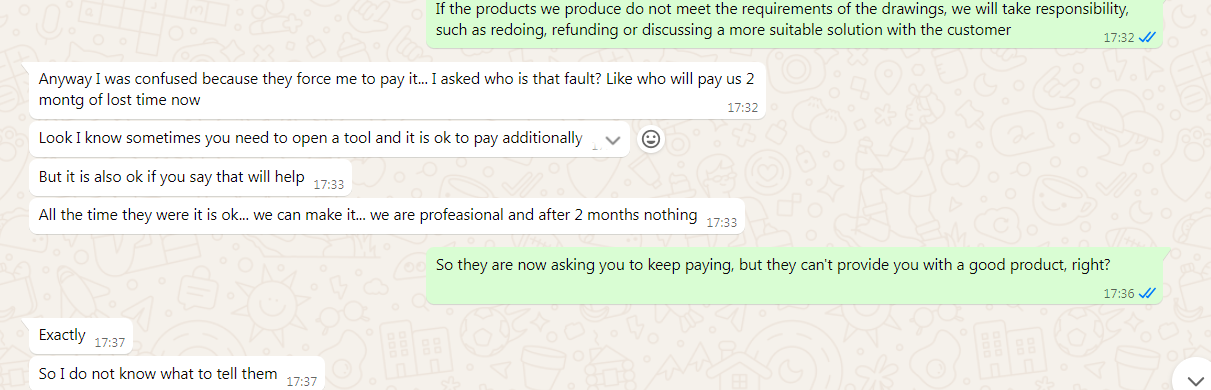

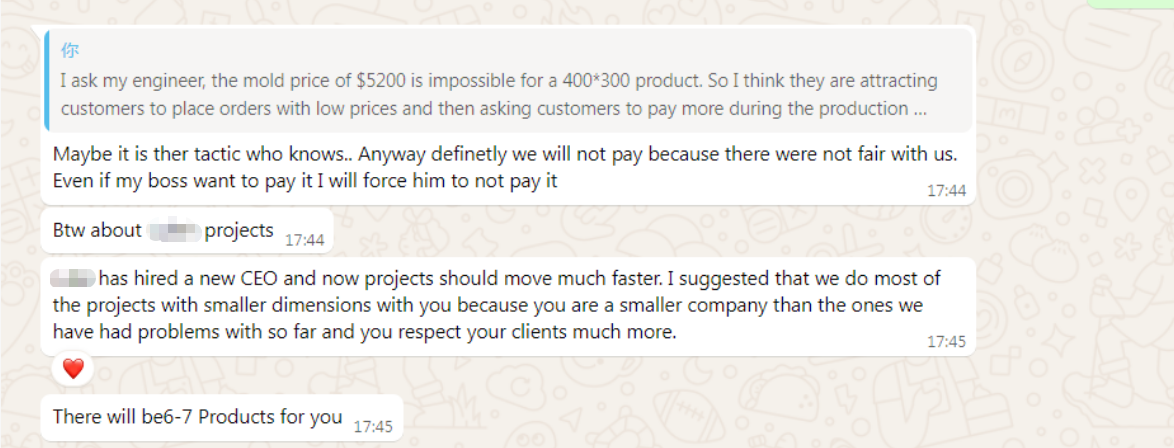

One of our clients learned this lesson the hard way: after paying $4,500 upfront for a mold that never worked, they lost two months of time-to-market — while the supplier kept asking for more money.

Here’s their story, and how BERGEK CNC stepped in with engineering expertise, transparent pricing, and reliable delivery to rebuild trust.

Table of Contents

The supplier quoted $5,200 for the mold.

The client paid $4,500 upfront.

But when the mold was delivered, the results were disastrous:

Critical dimensions did not match the drawings.

Parts showed shrinkage, deformation, and poor fit.

Instead of fixing the problem, the supplier demanded another $2,000 for “changes.”

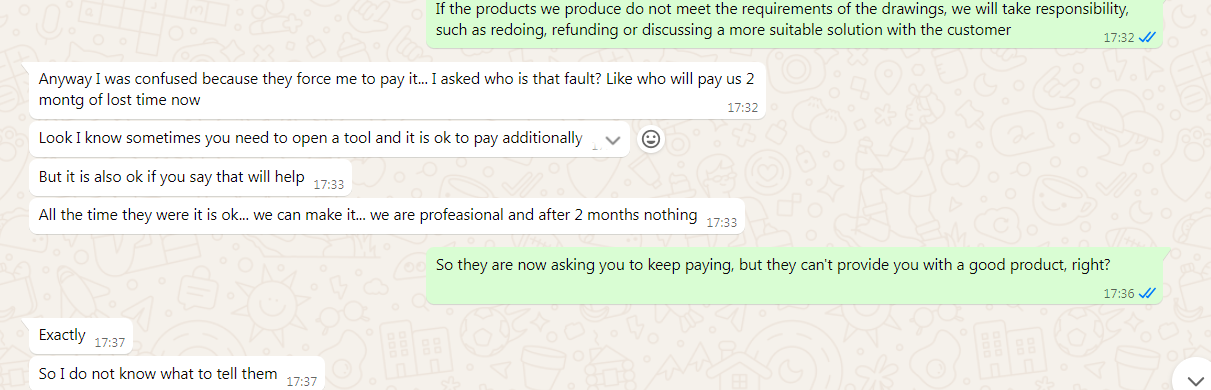

The client reluctantly considered it, hoping it would solve the issue. But after two more months, nothing improved. Worse: the supplier kept insisting on further payments.

“We lost almost $5k, two months of time, and still have no usable product. Now they are asking for more. This is not fair at all.”

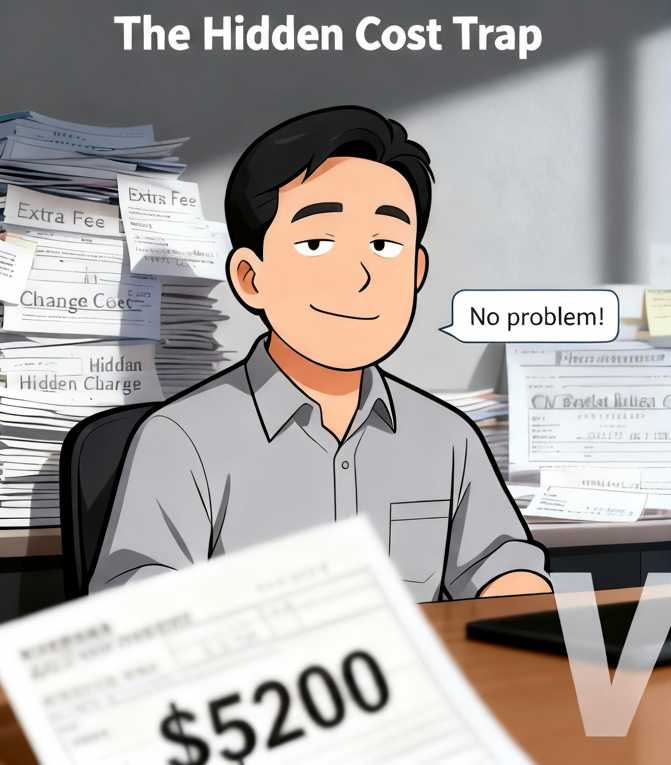

False Promises

At the start: “No problem, we can make it.”

After two months: nothing delivered.

The Low-Price Trap

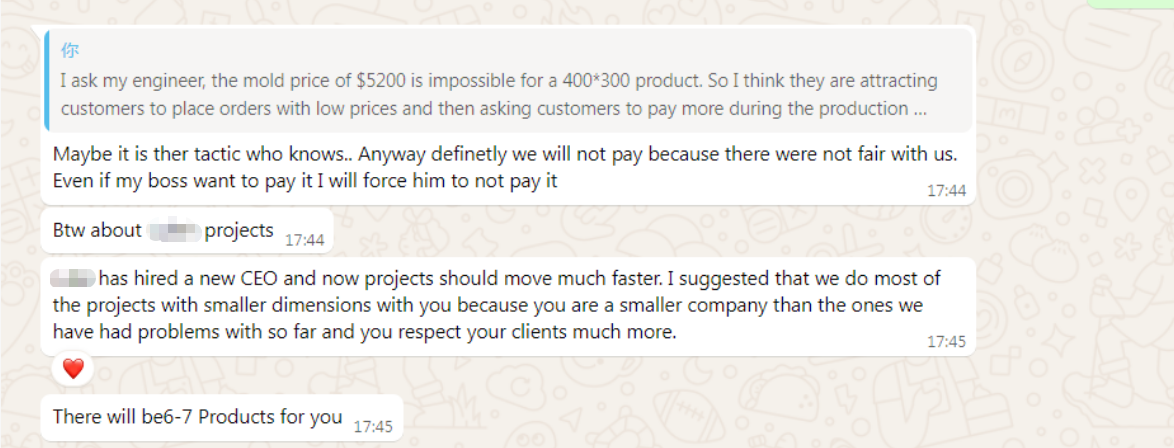

Unrealistically cheap quote ($5,200 for a 400×300 mold).

Hidden add-ons to increase cost later.

Lack of Accountability

Refusing to take responsibility for their mistakes.

Still demanding more money despite repeated failures.

Time Lost = Money Lost

Two months wasted with no progress.

Opportunity cost far greater than the $4,500 already spent.

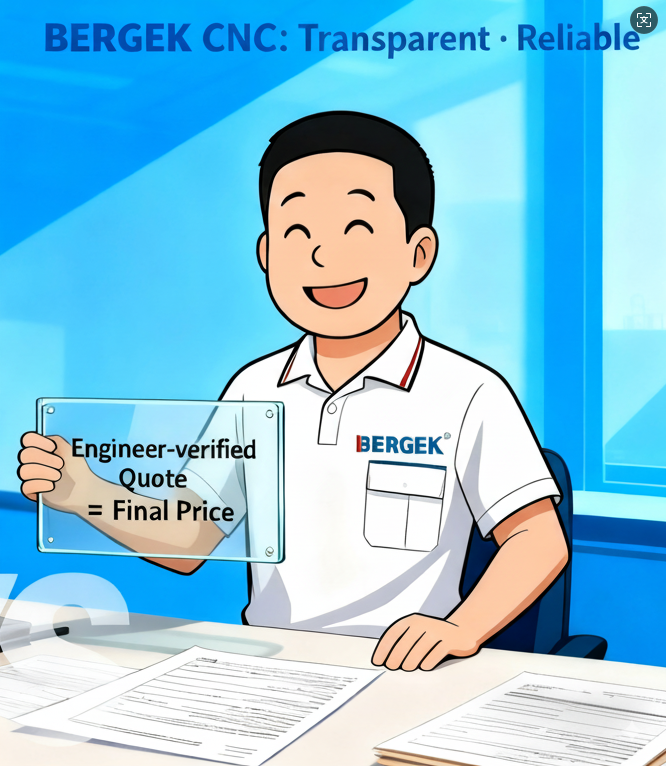

When the client reached out to BERGEK, we approached the problem with honesty and engineering insight.

✅ Engineer-Verified Quotes — No Hidden Costs

Every quote is engineer-verified.

First Price = Final Price. No hidden fees.

DFM (Design for Manufacturability) checks are done upfront.

✅ ISO-Certified Quality & Advanced Machining Capabilities

ISO 9001 & ISO 13485 certified for industrial and medical-grade standards.

Equipped for complex 5-axis CNC machining and multi-material production when projects demand high precision.

In-process inspections ensure problems are caught early, not after delivery.

✅ One Sales Engineer — All Your Answers

A single point of contact ensures clear accountability.

No confusion, no passing responsibility.

✅ Flexible Traceability & On-Demand Reports

Project-based records for critical jobs.

On-demand inspection reports.

Efficiency-driven approach — no unnecessary paperwork.

✅ Delivery = Peace of Mind

Beyond machining: hardware assembly and custom packaging available.

Quality issues solved immediately — not postponed as “after-sales.”

Products delivered ready to use or ready for market.

They soon shifted 6–7 new product projects to BERGEK. In the next phase, they even entrusted us with assembly, packaging, and QR code integration for their laser equipment — proof that trust had been rebuilt.

When selecting a CNC machining or mold-making partner, ask:

Is the quote engineer-verified and final?

Do they hold ISO certifications?

Can they handle complex 5-axis or multi-material projects when required?

Will you have one accountable contact?

Can they deliver market-ready solutions (assembly, packaging), not just parts?

This client’s story shows that cheap quotes don’t mean low costs.

The wrong supplier cost them $4,500 upfront and two months of lost time-to-market, with nothing usable in hand.

BERGEK CNC offers a different path:

Engineer-Verified Quotes, No Hidden Costs

ISO 9001 & ISO 13485 Certified Quality + Advanced 5-Axis Machining

98.7% On-Time Delivery, Flexible Scheduling

One Sales Engineer, Transparent Communication

Delivery = Peace of Mind: Assembly + Packaging

READ MORE:

From Inquiry to Delivery: Step-by-Step CNC Machining Supplier Workflow

Medical Device Manufacturing: Why Choose an ISO Certified CNC Supplier

Understanding the True Cost of Custom CNC Machined Components

How to Source a Trusted 5-Axis CNC Machining Factory for Automotive Parts

Price Comparison: CNC Machining vs. Other Manufacturing Methods

Prototype to Production: Custom 5-Axis CNC Machining Services Explained

Why ISO 9001 Certification Matters When Choosing a CNC Machining Supplier

READ MORE:

- How to Tell If a CNC Machining Factory Is Truly Trustworthy?

- Why Designers Must Share Their Design Intent with CNC Machining Manufacturers

- From Inquiry to Delivery: Step-by-Step CNC Machining Supplier Workflow

- Medical Device Manufacturing: Why Choose an ISO Certified CNC Supplier

- OEM & ODM CNC Machining Services: What Buyers Need to Know

- Understanding the True Cost of Custom CNC Machined Components

- How to Source a Trusted 5-Axis CNC Machining Factory for Automotive Parts

- Price Comparison: CNC Machining vs. Other Manufacturing Methods

- Prototype to Production: Custom 5-Axis CNC Machining Services Explained

Case Study: How a Failed Mold Wasted $4,500 and Two Months of Time-to-Market — And Why the Client Chose BERGEK CNC Instead

In manufacturing, the success of a product often depends on the quality of the mold used to produce it.

One of our clients learned this lesson the hard way: after paying $4,500 upfront for a mold that never worked, they lost two months of time-to-market — while the supplier kept asking for more money.

Here’s their story, and how BERGEK CNC stepped in with engineering expertise, transparent pricing, and reliable delivery to rebuild trust.

Table of Contents

The supplier quoted $5,200 for the mold.

The client paid $4,500 upfront.

But when the mold was delivered, the results were disastrous:

Critical dimensions did not match the drawings.

Parts showed shrinkage, deformation, and poor fit.

Instead of fixing the problem, the supplier demanded another $2,000 for “changes.”

The client reluctantly considered it, hoping it would solve the issue. But after two more months, nothing improved. Worse: the supplier kept insisting on further payments.

“We lost almost $5k, two months of time, and still have no usable product. Now they are asking for more. This is not fair at all.”

False Promises

At the start: “No problem, we can make it.”

After two months: nothing delivered.

The Low-Price Trap

Unrealistically cheap quote ($5,200 for a 400×300 mold).

Hidden add-ons to increase cost later.

Lack of Accountability

Refusing to take responsibility for their mistakes.

Still demanding more money despite repeated failures.

Time Lost = Money Lost

Two months wasted with no progress.

Opportunity cost far greater than the $4,500 already spent.

When the client reached out to BERGEK, we approached the problem with honesty and engineering insight.

✅ Engineer-Verified Quotes — No Hidden Costs

Every quote is engineer-verified.

First Price = Final Price. No hidden fees.

DFM (Design for Manufacturability) checks are done upfront.

✅ ISO-Certified Quality & Advanced Machining Capabilities

ISO 9001 & ISO 13485 certified for industrial and medical-grade standards.

Equipped for complex 5-axis CNC machining and multi-material production when projects demand high precision.

In-process inspections ensure problems are caught early, not after delivery.

✅ One Sales Engineer — All Your Answers

A single point of contact ensures clear accountability.

No confusion, no passing responsibility.

✅ Flexible Traceability & On-Demand Reports

Project-based records for critical jobs.

On-demand inspection reports.

Efficiency-driven approach — no unnecessary paperwork.

✅ Delivery = Peace of Mind

Beyond machining: hardware assembly and custom packaging available.

Quality issues solved immediately — not postponed as “after-sales.”

Products delivered ready to use or ready for market.

They soon shifted 6–7 new product projects to BERGEK. In the next phase, they even entrusted us with assembly, packaging, and QR code integration for their laser equipment — proof that trust had been rebuilt.

When selecting a CNC machining or mold-making partner, ask:

Is the quote engineer-verified and final?

Do they hold ISO certifications?

Can they handle complex 5-axis or multi-material projects when required?

Will you have one accountable contact?

Can they deliver market-ready solutions (assembly, packaging), not just parts?

This client’s story shows that cheap quotes don’t mean low costs.

The wrong supplier cost them $4,500 upfront and two months of lost time-to-market, with nothing usable in hand.

BERGEK CNC offers a different path:

Engineer-Verified Quotes, No Hidden Costs

ISO 9001 & ISO 13485 Certified Quality + Advanced 5-Axis Machining

98.7% On-Time Delivery, Flexible Scheduling

One Sales Engineer, Transparent Communication

Delivery = Peace of Mind: Assembly + Packaging

READ MORE:

From Inquiry to Delivery: Step-by-Step CNC Machining Supplier Workflow

Medical Device Manufacturing: Why Choose an ISO Certified CNC Supplier

Understanding the True Cost of Custom CNC Machined Components

How to Source a Trusted 5-Axis CNC Machining Factory for Automotive Parts

Price Comparison: CNC Machining vs. Other Manufacturing Methods

Prototype to Production: Custom 5-Axis CNC Machining Services Explained

Why ISO 9001 Certification Matters When Choosing a CNC Machining Supplier

READ MORE:

- How to Tell If a CNC Machining Factory Is Truly Trustworthy?

- Why Designers Must Share Their Design Intent with CNC Machining Manufacturers

- From Inquiry to Delivery: Step-by-Step CNC Machining Supplier Workflow

- Medical Device Manufacturing: Why Choose an ISO Certified CNC Supplier

- OEM & ODM CNC Machining Services: What Buyers Need to Know

- Understanding the True Cost of Custom CNC Machined Components

- How to Source a Trusted 5-Axis CNC Machining Factory for Automotive Parts

- Price Comparison: CNC Machining vs. Other Manufacturing Methods

- Prototype to Production: Custom 5-Axis CNC Machining Services Explained