Advanced Applications: CNC Machined Aluminum Parts for Robotics and Automation

Introduction

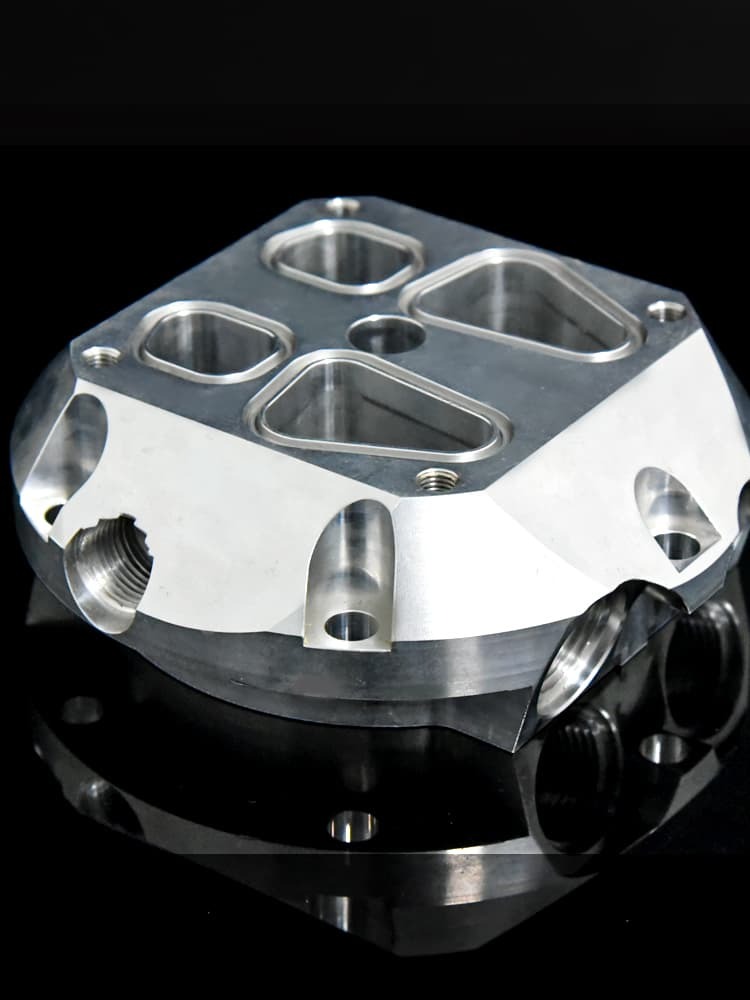

Robotics and automation demand mechanical components that are precise, durable, and optimized for integration. CNC aluminum part for robotics and machined aluminum component have become the gold standard for such applications. This article delves into how advanced CNC machining enables reliable solutions for automation, highlighting manufacturing, finishing, and industrial use cases.

Why CNC Aluminum Parts for Robotics?

Robotics projects require components that can withstand repeated motion, load, and environmental factors. CNC aluminum block machining provides:

Consistent accuracy: Essential for robotic arms, joints, and mounts.

Custom designs: Every application can be uniquely tailored using custom aluminum machining.

Reduced weight: Lightweight aluminum improves speed and energy efficiency.

Key Manufacturing Methods

Machined aluminum chassis and CNC aluminum structural component manufacturing involves several advanced steps:

Multi-axis CNC machining: Produces complex parts required for high-mobility robotics.

Tight tolerance CNC part: Ensures all components interact smoothly and reliably.

Functional prototype CNC part: Facilitates quick iteration and design optimization.

High-precision CNC aluminum and quality-controlled surface finishing provide robust mechanical performance and long-term reliability.

Surface Finishing for Robotics

Surface quality is critical in robotics:

Green anodized aluminum part: Reduces wear and corrosion.

Decorative CNC finishes: Enable color coding and easy identification.

Eco-friendly surface treatments: Meet sustainability goals of modern automation.

Industrial Applications

Robotics grippers, arms, and mounts

Precision automation modules

Aerospace and semiconductor robotics

Industrial automation chassis

Aluminum component for automation and custom machined housing offer the flexibility and resilience demanded by fast-moving industries.

Conclusion

CNC machined aluminum parts empower engineers to design robotics and automation systems that are robust, lightweight, and adaptable. Advanced machining and finishing processes ensure every component delivers on performance and reliability, supporting innovation in manufacturing and automation.

CNC aluminum part for robotics

machined aluminum component

custom aluminum machining

CNC aluminum block machining

machined aluminum chassis

CNC aluminum structural component

tight tolerance CNC part

multi-axis CNC machining

high-precision CNC aluminum

functional prototype CNC part

decorative CNC finishes

eco-friendly surface treatments

quality-controlled surface finishing

robotics parts 5-axis CNC machining

custom machined housing

fast sample delivery

anodized aluminum CNC machining

green anodized aluminum part

machined electronic enclosure

aluminum CNC manufacturing service

industrial-grade CNC components

post-machining inspection

precision CNC milling part

supply chain CNC solutions

micro-machining CNC shop

industrial CNC enclosure

aluminum component for automation

CNC machining aerospace component

CNC enclosure for electronics

custom CNC batch finishing

complex CNC aluminum machining

CNC anodized component manufacturer

anodized aluminum enclosure

CNC mechanical part anodized

green CNC anodized finish

CNC anodized green part

machined aluminum component

high-tolerance machined parts

CNC precision parts

custom post-processing CNC parts

one-stop CNC post-processing

ODM/OEM CNC machining

Tags: CNC aluminum part for robotics, machined aluminum component, custom aluminum machining, multi-axis CNC machining, aluminum component for automation

READ MORE:

Optimizing Performance: Precision CNC Milling for Advanced Aluminum Enclosures

Supply Chain Advantages of Custom CNC Aluminum Enclosure Manufacturing

Innovations in Surface Finishing: Anodized Aluminum Enclosures for Electronics

The Value of CNC Machined Aluminum Housings for Industrial Electronic Applications

Advanced Applications: CNC Machined Aluminum Parts for Robotics and Automation

Introduction

Robotics and automation demand mechanical components that are precise, durable, and optimized for integration. CNC aluminum part for robotics and machined aluminum component have become the gold standard for such applications. This article delves into how advanced CNC machining enables reliable solutions for automation, highlighting manufacturing, finishing, and industrial use cases.

Why CNC Aluminum Parts for Robotics?

Robotics projects require components that can withstand repeated motion, load, and environmental factors. CNC aluminum block machining provides:

Consistent accuracy: Essential for robotic arms, joints, and mounts.

Custom designs: Every application can be uniquely tailored using custom aluminum machining.

Reduced weight: Lightweight aluminum improves speed and energy efficiency.

Key Manufacturing Methods

Machined aluminum chassis and CNC aluminum structural component manufacturing involves several advanced steps:

Multi-axis CNC machining: Produces complex parts required for high-mobility robotics.

Tight tolerance CNC part: Ensures all components interact smoothly and reliably.

Functional prototype CNC part: Facilitates quick iteration and design optimization.

High-precision CNC aluminum and quality-controlled surface finishing provide robust mechanical performance and long-term reliability.

Surface Finishing for Robotics

Surface quality is critical in robotics:

Green anodized aluminum part: Reduces wear and corrosion.

Decorative CNC finishes: Enable color coding and easy identification.

Eco-friendly surface treatments: Meet sustainability goals of modern automation.

Industrial Applications

Robotics grippers, arms, and mounts

Precision automation modules

Aerospace and semiconductor robotics

Industrial automation chassis

Aluminum component for automation and custom machined housing offer the flexibility and resilience demanded by fast-moving industries.

Conclusion

CNC machined aluminum parts empower engineers to design robotics and automation systems that are robust, lightweight, and adaptable. Advanced machining and finishing processes ensure every component delivers on performance and reliability, supporting innovation in manufacturing and automation.

CNC aluminum part for robotics

machined aluminum component

custom aluminum machining

CNC aluminum block machining

machined aluminum chassis

CNC aluminum structural component

tight tolerance CNC part

multi-axis CNC machining

high-precision CNC aluminum

functional prototype CNC part

decorative CNC finishes

eco-friendly surface treatments

quality-controlled surface finishing

robotics parts 5-axis CNC machining

custom machined housing

fast sample delivery

anodized aluminum CNC machining

green anodized aluminum part

machined electronic enclosure

aluminum CNC manufacturing service

industrial-grade CNC components

post-machining inspection

precision CNC milling part

supply chain CNC solutions

micro-machining CNC shop

industrial CNC enclosure

aluminum component for automation

CNC machining aerospace component

CNC enclosure for electronics

custom CNC batch finishing

complex CNC aluminum machining

CNC anodized component manufacturer

anodized aluminum enclosure

CNC mechanical part anodized

green CNC anodized finish

CNC anodized green part

machined aluminum component

high-tolerance machined parts

CNC precision parts

custom post-processing CNC parts

one-stop CNC post-processing

ODM/OEM CNC machining

Tags: CNC aluminum part for robotics, machined aluminum component, custom aluminum machining, multi-axis CNC machining, aluminum component for automation

READ MORE:

Optimizing Performance: Precision CNC Milling for Advanced Aluminum Enclosures

Supply Chain Advantages of Custom CNC Aluminum Enclosure Manufacturing

Innovations in Surface Finishing: Anodized Aluminum Enclosures for Electronics

The Value of CNC Machined Aluminum Housings for Industrial Electronic Applications