Custom CNC Machined Stainless Steel & Plastic Components

We provide OEM CNC turning and milling services for hybrid assemblies using stainless steel and high-performance engineering plastics. These parts are used in automation, mechanical transmission, insulation, and fluid systems.

Materials: Stainless Steel (304/316), POM, Nylon, PTFE, UHMW-PE

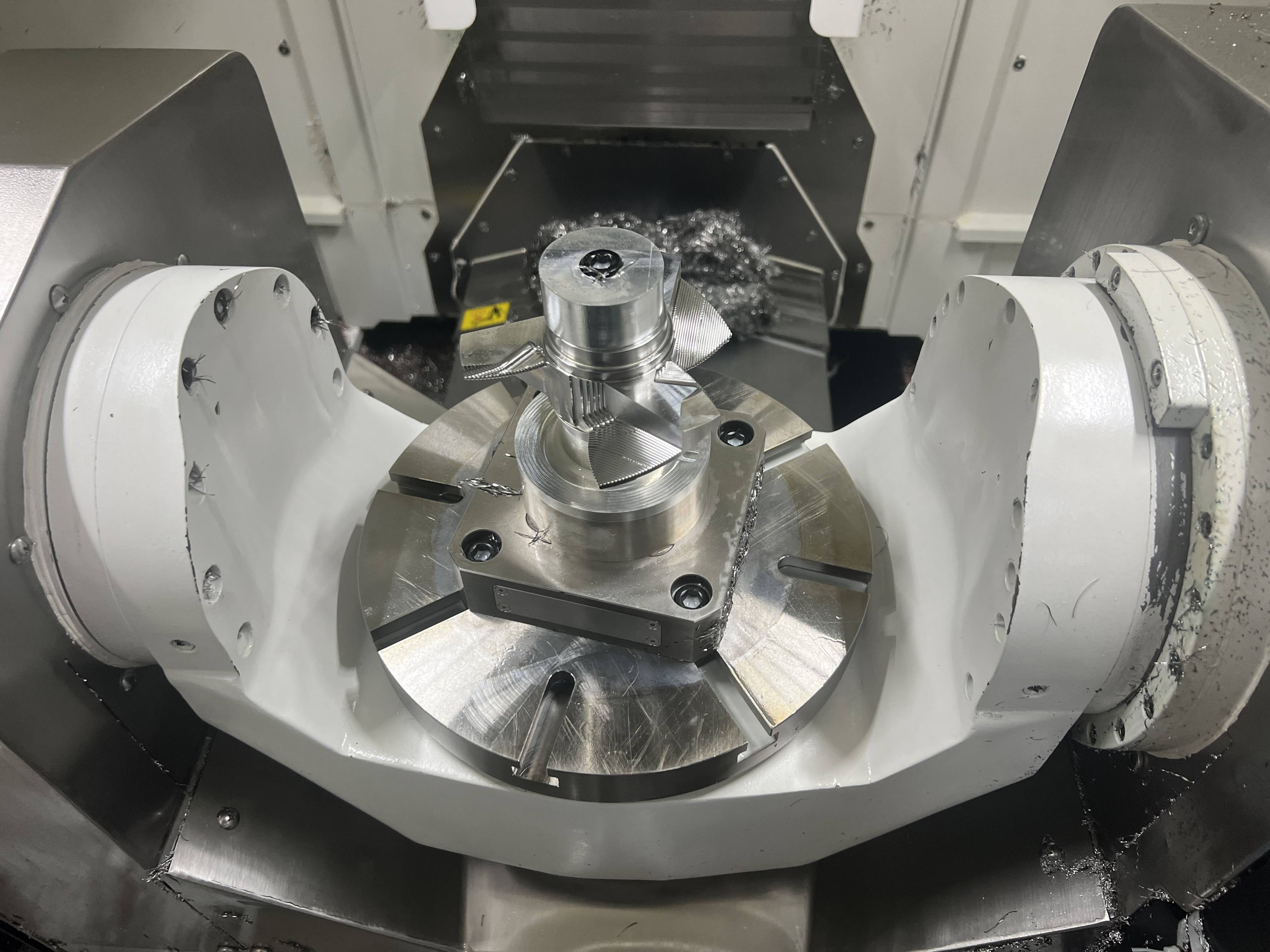

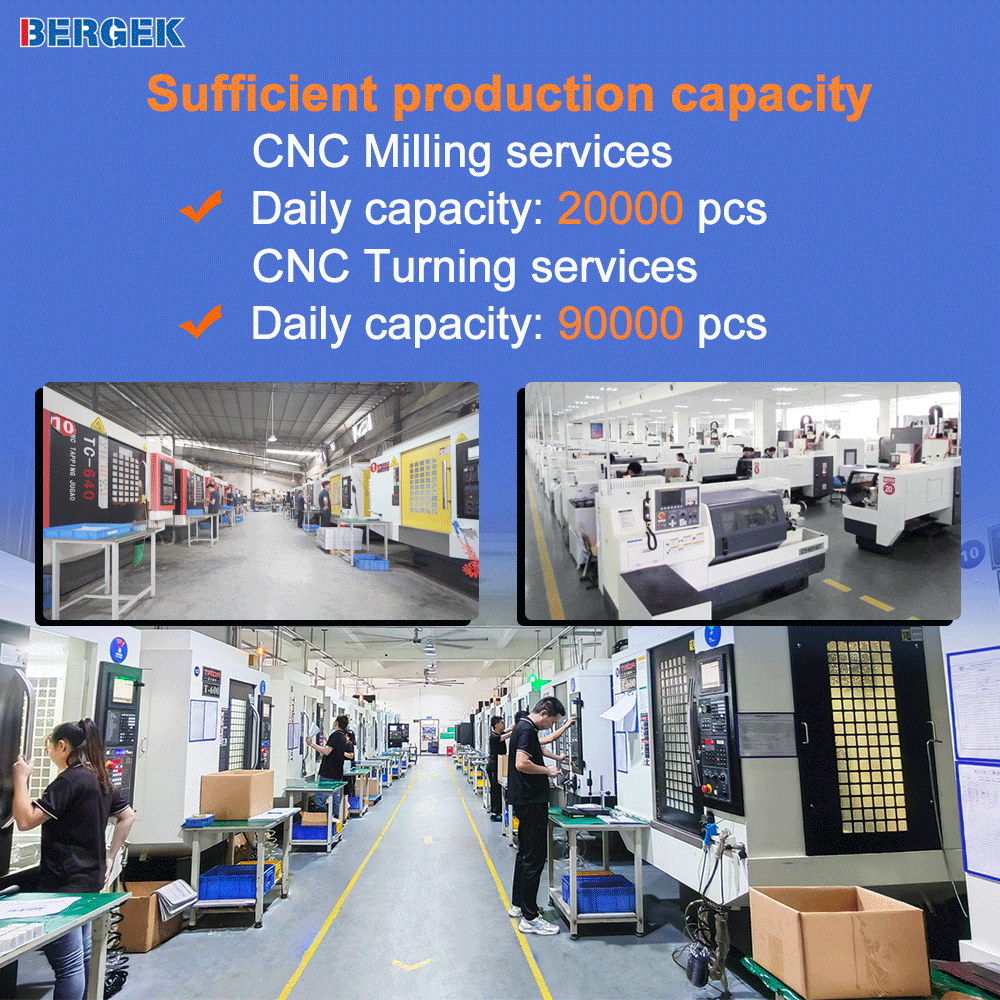

Machining Capabilities: CNC Turning, Milling, Drilling, Slotting

Plastic Component Type: Insulating sleeves, gears, guides, clamps

Metal Component Type: Threaded shafts, bearing housings, flanges

Tolerance: ±0.01mm for metal, ±0.03mm for plastic

Finish: Machined, Polished, Deburred

Color Options: White, Black, Natural (Plastic)

Thermal Resistance: Up to 150°C (PTFE/UHMW)

Wear Resistance: High with POM/Nylon

Corrosion Resistance: Stainless steel & PTFE resistant to most chemicals

Applications: Mechanical transmission, food machinery, packaging equipment, fluid control

Thread Support: Metric/UNC/NPT

Part Diameter: 5mm – 200mm

Wall Thickness: ≥0.5mm

CAD Formats: STEP, IGS, DXF, STL

Post Processing: Ultrasonic cleaning, deburring, laser marking

Machinery: Swiss lathe, CNC mill-turn center

Fixture System: Independent fixture for plastic and metal

Sample Lead Time: 5–7 days

Batch Volume: 10–1000 pieces

OEM/ODM: Accepted

Packaging: Cleanroom bagged or foam protected

Quality System: ISO9001:2015 certified

Inspection: Calipers, CMM, Thread Gauge

Insulation Performance: Plastic parts tested to 500V/mil

Moisture Resistance: Excellent with POM/PTFE

Cost Efficiency: Ideal for high wear-low load situations

Shipping: Global logistics via FedEx, UPS, DHL

Repeatability: ±0.005mm for metal, ±0.02mm for plastic

Environment Compliance: RoHS & FDA compliant plastics available

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-