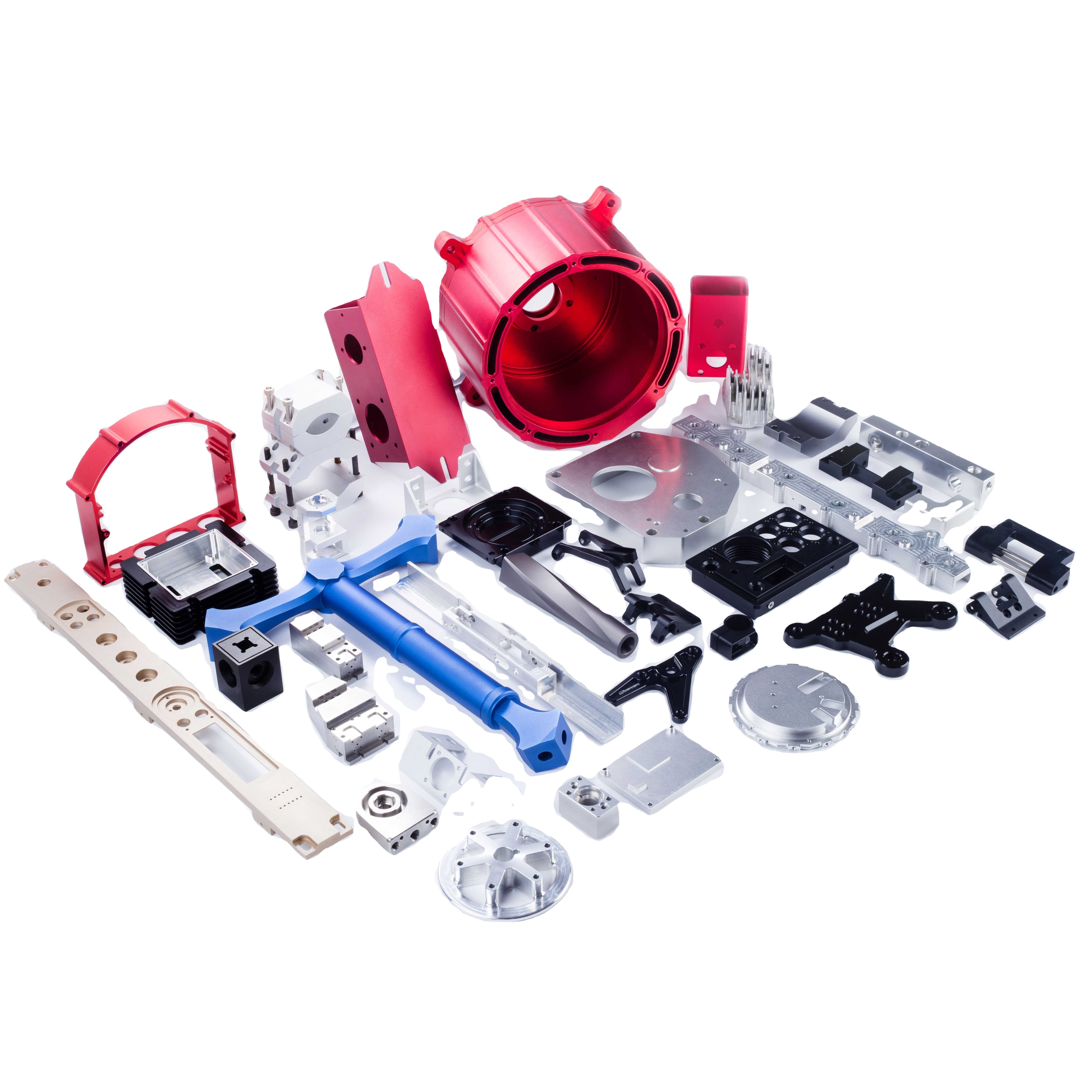

Precision CNC Machined Stainless Steel & Aluminum Components

We offer rapid CNC prototyping and production of stainless steel and aluminum components. Our capabilities support high-precision threading, sealing surfaces, and finned heat dissipation designs.

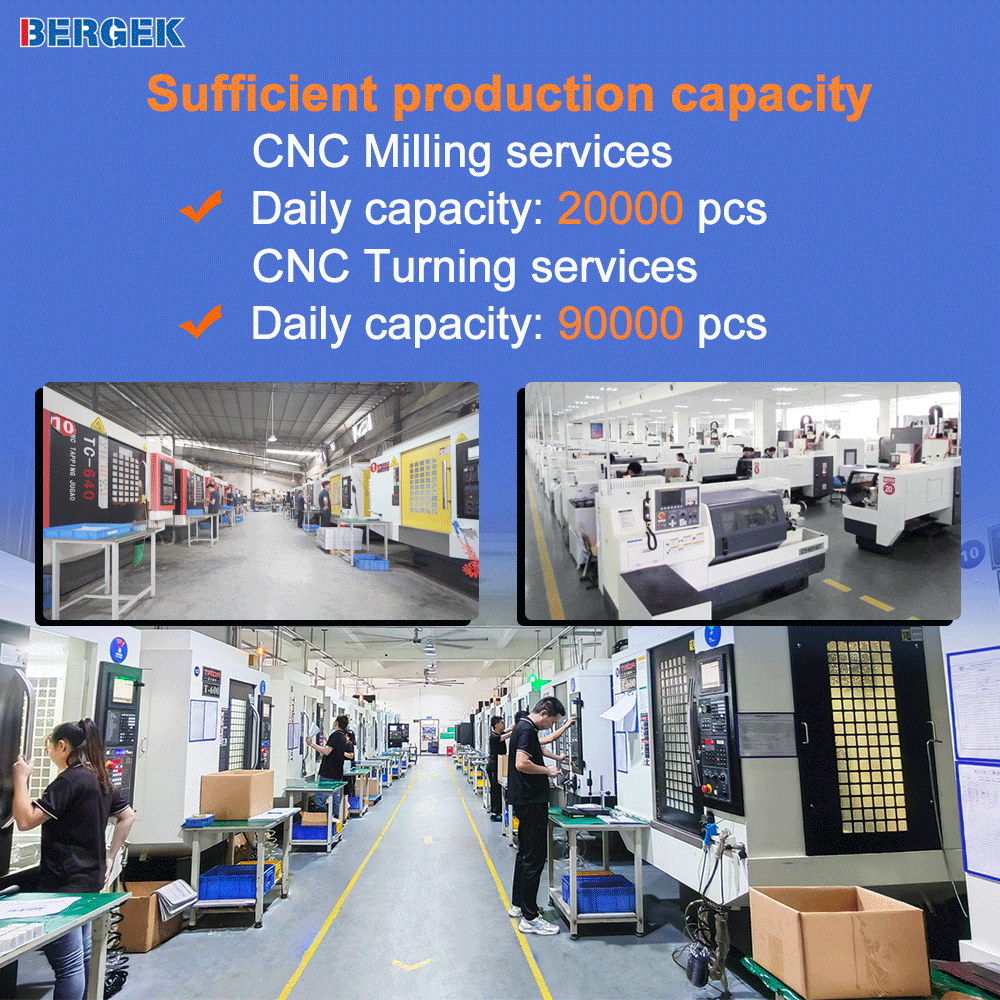

Machining Capabilities: CNC Turning, Milling, Boring, Tapping

Materials: SS304, SS316, 6061/7075 Aluminum

Part Types: Threaded shafts, sealing plugs, heat sinks, valve bodies

Tolerance: ±0.01mm (Turning) / ±0.02mm (Milling)

Threading: Internal/External (Metric, UNF, NPT, BSPT)

Design Features: Radial fins, concentricity control, flow channels

Surface Finish: Machined, Brushed, Light Polished

Machining Tools: Multi-axis CNC lathe + vertical milling center

Wall Thickness: ≥ 0.5mm

Diameter Range: 5mm – 150mm

Heat Dissipation Design: Yes (finned and hollowed parts)

Application Industries: HVAC, Robotics, Hydraulics, Automation, Aerospace

CAD Support: STEP, DWG, IGS, DXF

Surface Protection: Optional passivation or anodizing

Inspection Tools: Caliper, CMM, Roughness Tester

Rapid Prototyping: 3–7 Days

Batch Production: Up to 1000 pcs

OEM Services: Available

Polishing Level: Ra 0.8 – 3.2μm

Deburring: Manual + Tumbling

Fixture Type: Soft jaw or precision collet

Surface Treatment: None / Anodizing / Passivation

Sealing Performance: Machined sealing faces supported

Corrosion Resistance: High (with SS316 and passivation)

Thermal Conductivity: High with aluminum fins

Toolpath Strategy: Turn-mill adaptive

MOQ: 10 pcs

Lead Time: 5–8 working days

Sample Availability: Upon request

Shipping Method: FedEx/DHL/UPS

Certifications: ISO9001, SGS

Repeat Tolerance: ±0.005mm

Environmental Standard: RoHS/REACH compliant

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

-

Custom 5 Axis Aluminum CNC Machining Parts – 6061/7075/2024/6082 High Precision Components

High-precision custom 5 axis aluminum CNC machining parts crafted from premium alloys such as 6061, 7075, 2024, and 6082, offering exceptional strength, durability, and precision for diverse industrial applications.¥0.00¥0.00 -

High Precision 5-Axis CNC Machining Parts Multi-Material Custom Components

This product includes high-precision 5-axis CNC machined parts made from aluminum, stainless steel, copper, brass, titanium, and engineering plastics. Widely used in automotive, aerospace, electronics, medical, and robotics industries. We provide drawing or sample-based customization, fast prototyping, strict quality control, and global delivery.¥0.00¥0.00 -

ISO 9001 Certified 5-Axis CNC Machining Manufacturer High Precision Custom Parts

We are an ISO 9001 certified manufacturer specializing in high precision 5-axis CNC machining. We provide custom CNC components in aluminum, stainless steel, brass, copper, and engineering plastics. Our products are widely used in automotive, aerospace, electronics, robotics, and industrial applications. OEM/ODM supported, fast delivery, strict quality control.¥0.00¥0.00 -

.jpg)

ISO 9001 Certified 5‑Axis CNC Machining | Custom Acrylic & Plastic Parts Manufacturer

We are an ISO 9001 certified manufacturer specializing in 5‑axis CNC machining for custom acrylic, plastic, and metal parts. Our advanced machining centers can produce highly complex, multi-surface components according to your drawings or samples. We serve clients worldwide with rapid prototyping, batch production, and one-stop custom CNC solutions.¥0.00¥0.00