Top 10 Design Mistakes That Reduce CNC Precision

Introduction — Design errors at the start can destroy CNC precision

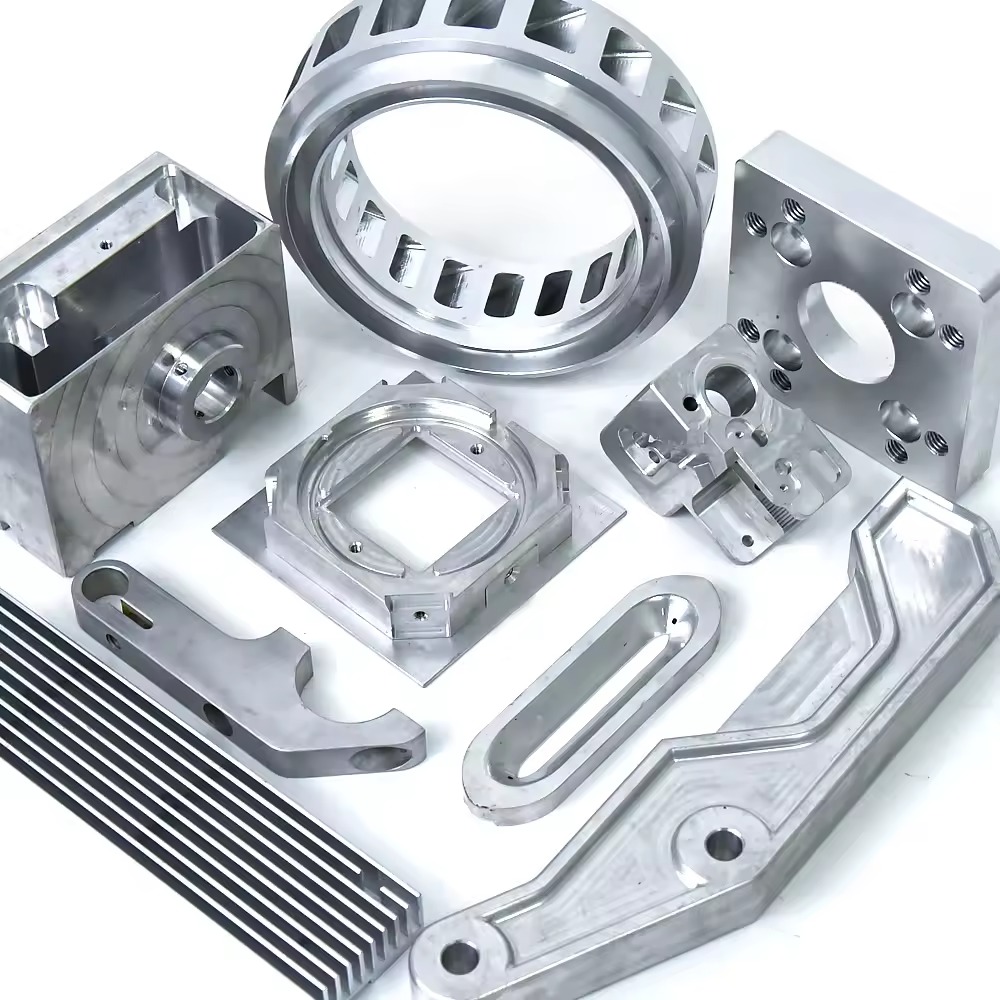

Many issues with precision cnc machining actually originate in the design phase, not in manufacturing itself. From rapid prototyping through production, a reliable cnc machining service is only as effective as the quality of the initial design. Ignoring key design principles can limit achievable accuracy long before a part reaches the shop floor.

Mistake #1–3 — Inadequate Wall Thickness / Deep Cavities / Small Chamfers

When machining aluminum parts, insufficient wall thickness, excessively deep cavities, or undersized chamfers make it difficult to produce an accurate aluminum prototype or custom metal parts. Such designs create instability, cause vibration, and increase the risk of distortion during cutting.

Mistake #4–6 — Dense Hole Patterns / Tiny Features / Uneven Thickness

In aluminum cnc machining and every cnc prototype, dense hole patterns, extremely small features, or inconsistent thickness introduce risk of instability and accuracy loss. Custom cnc machining can help, but the best strategy is to design for manufacturability up front and avoid high-risk geometries.

Mistake #7–8 — Multi-Face Design Leading to Clamping Errors / Undefined Datum

Multi-face features and unclear datum references are a common source of cumulative error. 5-axis cnc machining helps by minimizing part flipping and reducing the chance of misalignment. A second round of precision cnc machining and rapid prototyping further controls these risks.

Mistake #9–10 — Unreasonable Tolerance Specs / Poor Assembly Chain Design

Setting a tight tolerance without understanding the assembly chain can backfire—leading to fits that don’t work or size drift over time. Here, the expertise of a cnc machining service and the use of custom metal parts make the difference between success and costly rework.

Conclusion — Design Quality Sets the Upper Limit for Machining Precision

The path to high-accuracy rapid prototyping is paved with robust design practices. Precision cnc machining, advanced aluminum cnc machining, and expert cnc machining service can only reach their full potential when built on a foundation of error-proof design and strategic prototype manufacturing.

READ MORE:

- Engineering Tips for High-Accuracy Prototype Manufacturing

- How Thermal Expansion Affects Precision CNC Machining

- Measuring Precision: CMM, Calipers, Profilometers Explained

- GD&T Essentials for CNC Precision Parts

- Benefits of 5-Axis CNC Machining in High-Precision Prototyping

- The Influence of Tool Wear on Prototype Accuracy

- How Fixturing Impacts Precision CNC Machining

- Achieving ±0.01mm Tolerance in CNC Prototyping

- What Defines “Precision” in CNC Machining? A Practical Guide