When Should Engineers Use 5-Axis Machining?

Introduction — 5-Axis Is Not “Luxury”; It’s a Tool When Required

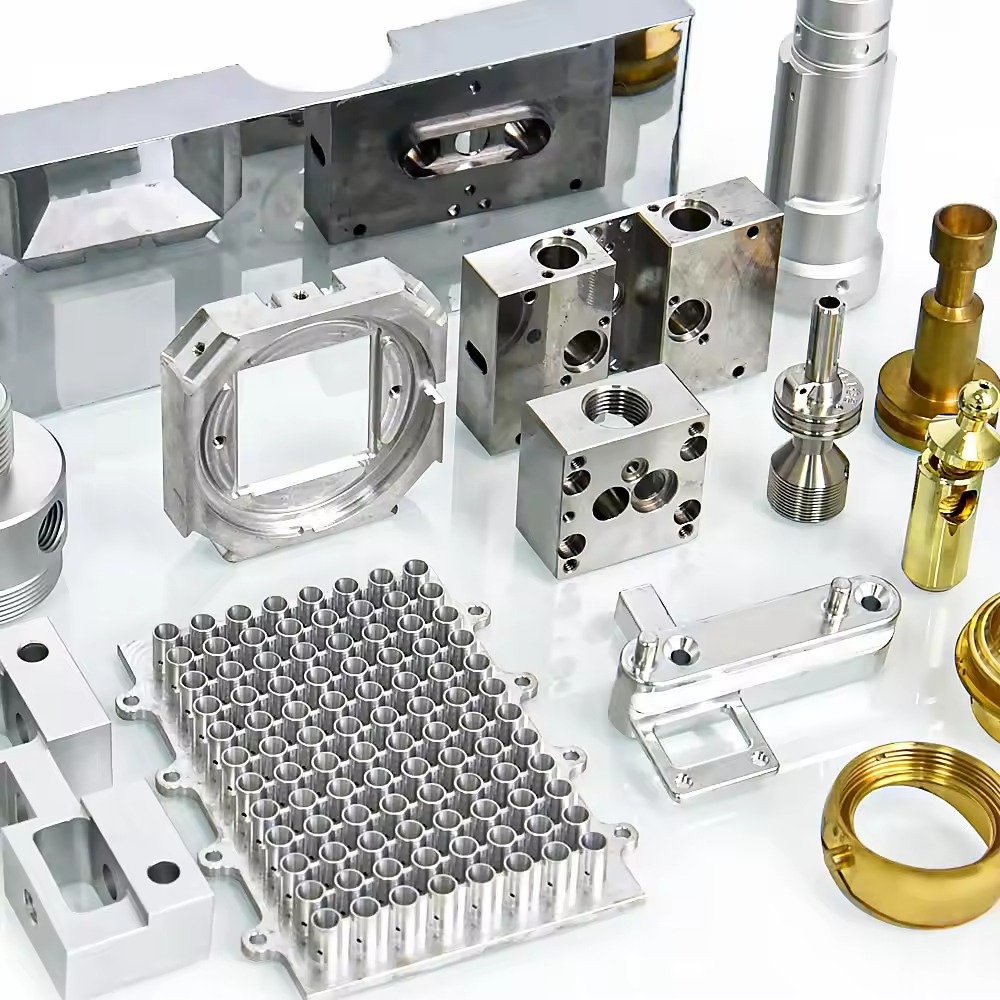

5-axis cnc machining delivers value by minimizing setups, boosting consistency, and handling intricate geometry. In rapid prototyping and precision cnc machining, it’s the right solution whenever complex shapes, multiple surfaces, or demanding tolerances are required.

Scenario #1 — Multi-Surface Structures, Chamfers, Deep Cavities

Typical 5-axis projects include housings, heat sinks, connectors, and complex bases. Machining aluminum parts for these applications enables true-to-design aluminum prototypes and custom metal parts, all with a single, efficient setup.

Scenario #2 — Freeform Curves and Ergonomic Enclosure Design

For complex curves, organic surfaces, and topology-optimized designs, 5-axis enables efficient tool access and minimal tool marks. Aluminum cnc machining of cnc prototype parts or custom cnc machining work is faster, more precise, and produces better finishes.

Scenario #3 — High-Precision Assemblies with Minimal Setup Error

Multiple re-fixturing increases cumulative errors. In both precision cnc machining and rapid prototyping, using 5-axis and a skilled cnc machining service keeps tolerances tight by reducing these manual steps.

Scenario #4 — Assembly Parts with Tight Tolerance and High Repeatability

5-axis is a must for robots, medical devices, aerospace, and automated equipment requiring tight tolerance and perfect alignment. Cnc machining service for these custom metal parts ensures every batch meets the highest standards.

Conclusion — 5-Axis: A Precision Tool, Not a Luxury

Engineers select 5-axis for accuracy and efficiency, not extravagance. Combine rapid prototyping, aluminum cnc machining, and advanced tool paths to achieve best-in-class results in prototype manufacturing and precision cnc machining. Choose 5-axis whenever part complexity or tolerance truly demands it.

READ MORE:

- CNC vs 3D Printing: Which Is Better for Metal Prototyping?

- What Causes Surface Defects in CNC Machining?

- Why Lead Time Varies for CNC Machined Prototypes

- How to Avoid Undercuts in CNC Prototype Design

- How to Ensure Tight Tolerance in Small Metal Components

- Best Practices for Designing CNC Machined Metal Housings

- How to Prepare 3D Files for CNC Machining

- Why Do CNC Machined Parts Warp? Causes and Solutions

- How to Reduce CNC Machining Cost for Prototypes