The Benefits of Using CNC Machining for Fast Metal Prototypes

Introduction

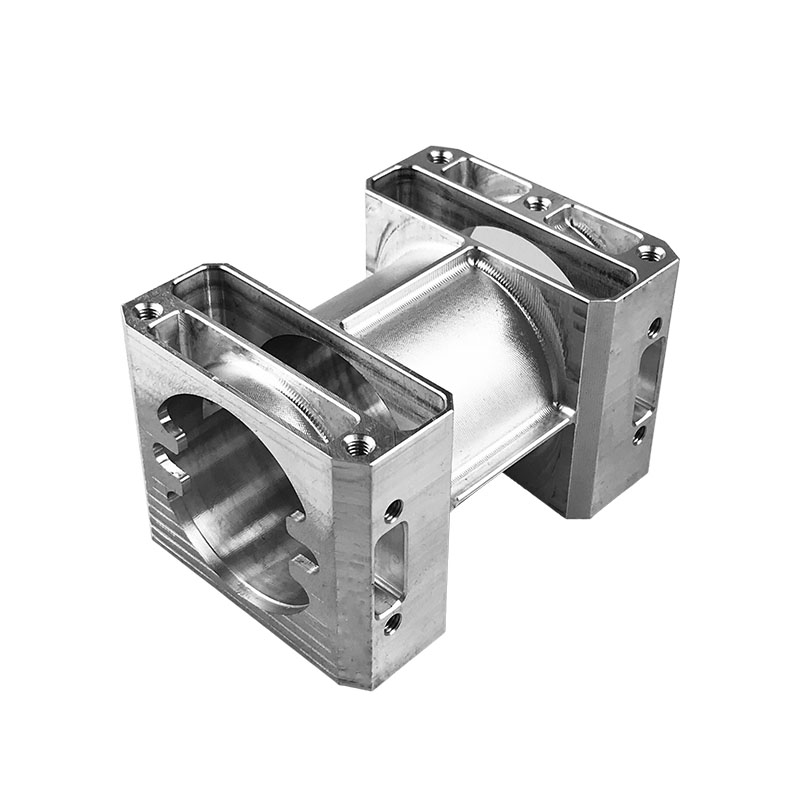

In the field of hardware development, speed and accuracy are essential when testing new concepts. Rapid prototyping allows engineers to quickly transform digital designs into real-world components. When it comes to producing metal prototypes, cnc machining service offers unique advantages in terms of turnaround, precision, and material compatibility.

1. Fast Iteration and Design Validation

Rapid prototyping is critical for early-stage projects because it provides fast feedback on design feasibility. With a reliable cnc machining service, teams can produce multiple iterations in a short time, refining geometry and function as required. Using precision cnc machining, each prototype is manufactured to tight specifications, allowing for accurate fit and functional testing.

This level of speed and control is possible thanks to mature cnc machining service workflows that streamline the transition from CAD to part.

2. Material Versatility and Functional Testing

One of the main benefits of CNC machining is the ability to work with various metals. Aluminum cnc machining is especially popular for fast prototyping due to its machinability and lightweight properties. When more demanding applications arise, custom metal parts made from steel, titanium, or other alloys can be produced.

Building an aluminum prototype provides important insights into mechanical strength, heat dissipation, and assembly compatibility. The flexibility to machine custom metal parts at low volumes allows engineers to validate performance in real-world scenarios.

When comparing different metal choices, aluminum cnc machining and the option to create other custom metal parts ensure that all functional requirements can be assessed before scaling production.

3. Complex Geometries and Advanced Capabilities

Modern projects often demand intricate shapes and challenging features. 5-axis cnc machining provides the ability to create complex surfaces and undercuts in a single operation, improving both speed and accuracy. Precision cnc machining further ensures that each detail is faithfully reproduced, regardless of design complexity.

The combination of precision cnc machining with 5-axis technology enables the production of highly functional, detailed prototypes that closely mirror final production parts.

4. Tolerance Control and Manufacturing Confidence

For functional prototypes, maintaining tight tolerance is essential. Machining aluminum parts to exact specifications guarantees that critical features will perform as intended during assembly and testing. Through precision cnc machining and robust cnc machining service, it is possible to meet strict tolerances required for reliable performance.

5. Supporting Efficient Prototype Manufacturing

Rapid prototyping supports the overall process of prototype manufacturing by reducing wait times and minimizing design risk. Early production of a cnc prototype helps uncover any manufacturing or design issues. As development continues, custom cnc machining can be used for iterative improvement and to support different prototype stages.

Conclusion

Using CNC machining for fast metal prototypes provides engineers with rapid feedback, material versatility, and precision. By leveraging cnc machining service, precision cnc machining, and advanced processes like 5-axis cnc machining, teams can develop prototypes that accelerate validation, reduce risk, and streamline the transition to full-scale manufacturing.

READ MORE:

- The Role of Precision CNC Machining in Fast Product Validation

- Cost Drivers in Rapid CNC Prototyping for Aluminum Parts

- Common Mistakes in Rapid CNC Prototyping and How to Avoid Them

- Why CNC Is the Most Reliable Technology for Metal Rapid Prototypes

- How Rapid Prototyping Reduces Engineering Risk Before Mass Production

- Rapid Prototyping vs Traditional Machining: What Engineers Need to Know

- Why Rapid Prototyping Is Critical in Early-Stage Hardware Development

- What Is Rapid CNC Prototyping? A Complete Engineer’s Guide to Precision and DFM

- Modern Engineering Success with Rapid Prototyping Custom Metal Aluminum and Precision CNC Machining